Title: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-EcoDragon on January 28, 2005, 11:38:56 pm

Well,

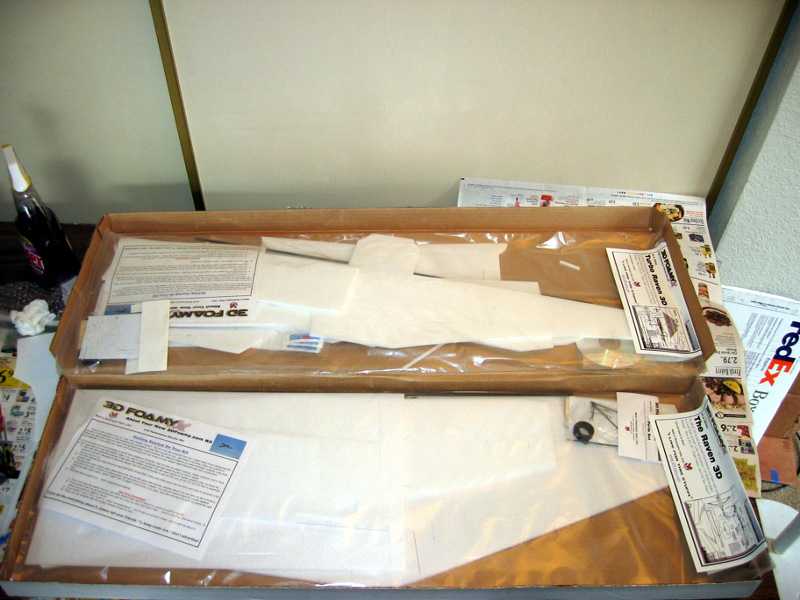

Through the wonders of modern debt technology, ie. a Credit Card, I should soon be in posession of the Raven from www.3dfoamy.com I am building one of these as a gift for a nephew, and one for me pretty soon.

My specs are

Plane: 3D Foamy Raven "Pro" package with Depron and G-Force wing, and Carbon Fiber Landing Gear kit.

Powerplant: AXI 2212/34

Prop: APC 11x4.7

Receiver: Berg 6*G III

Electronic speed control: Castle Creations Phoenix 10

Servos: (4) Hitec Hs-55 sub micros

two 6 inch servo extensions

Testors Spray Enamel in Dark Red 1207 , Black 1247, Gold 1244, Dark Blue 1211, Silver 1246 (mist over blue canopy), and a Testors Gold Paint Marker (I wish I bought this sooner, it works great!)

Batteries: Apogee High Discharge 830 mAh 3cell Lithium Polymer packs

Apache 2500 LiPo Safe Charger (LiPo packs are known to blow up, like. . . for real!)

All up ready to fly weight with Apogee 830 3 cell, and after a few rebuilds, and a top creations AXI stick mount is now 12.9 oz.

Some of the needed gear has already arrived, but I am still waiting on the Kit, motor, Batteries, Charger.

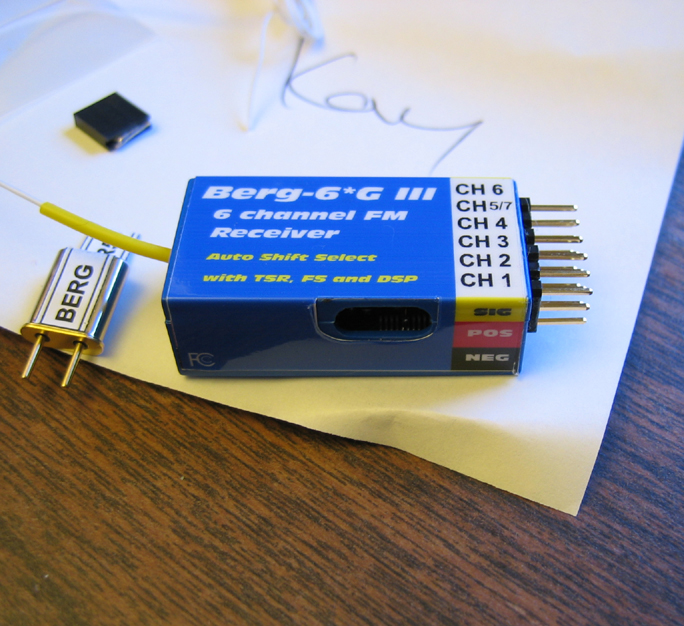

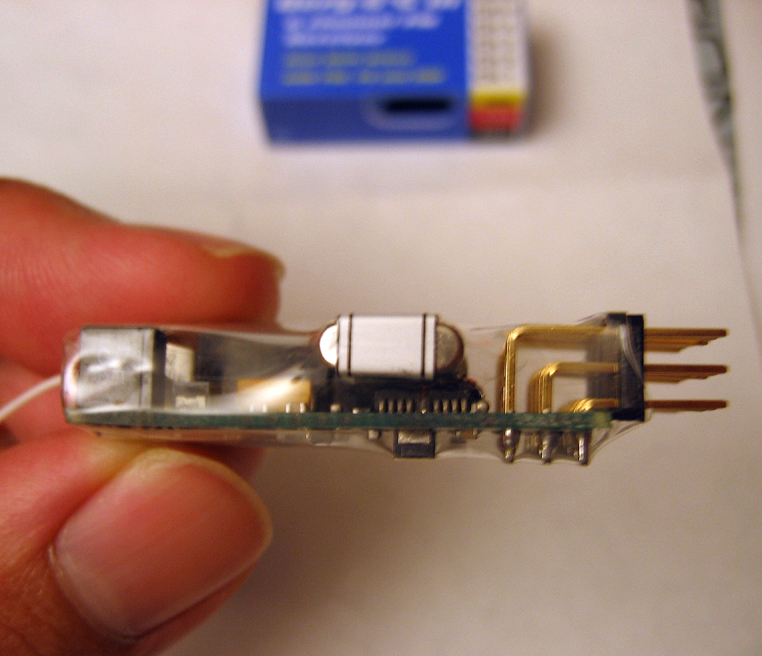

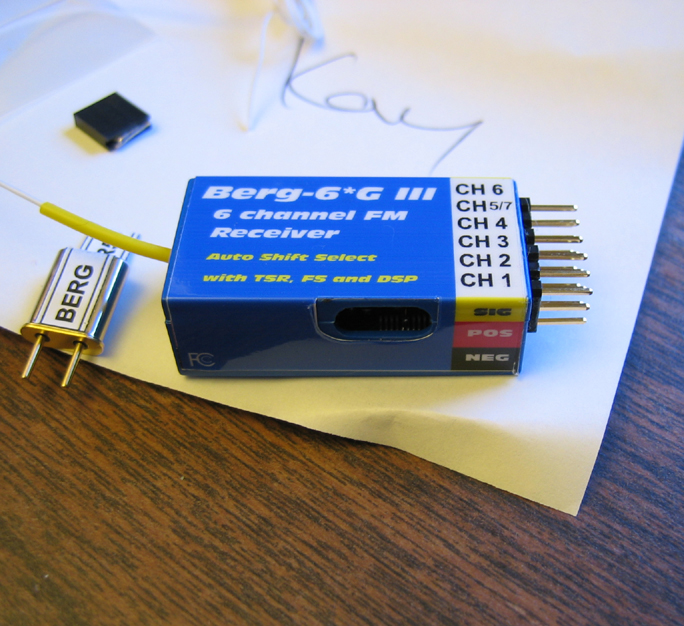

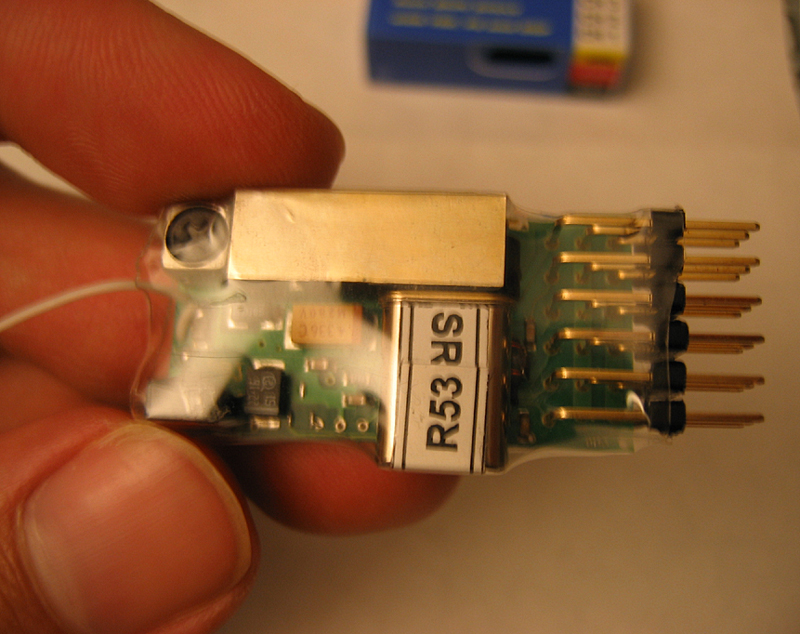

Here is the Berg 6* G III Receiver as it came out of the package today. These are very small, light, and jam packed with awesome features, see the link below if interested.

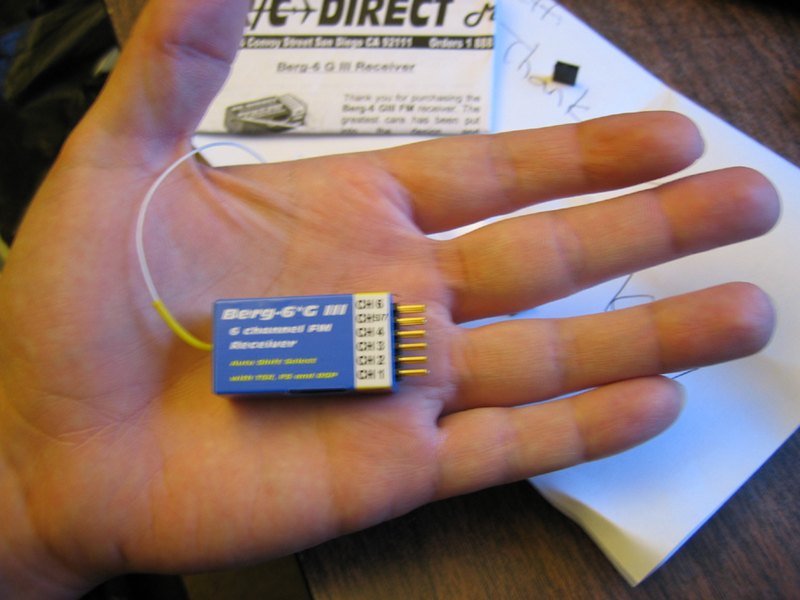

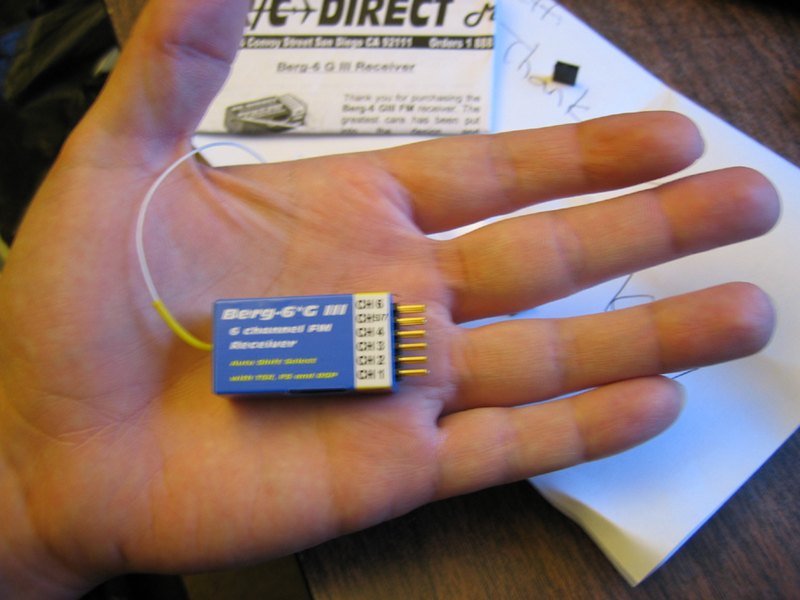

See, it's pretty small. . . and as I said pretty light at 13 grams. . .but. . .

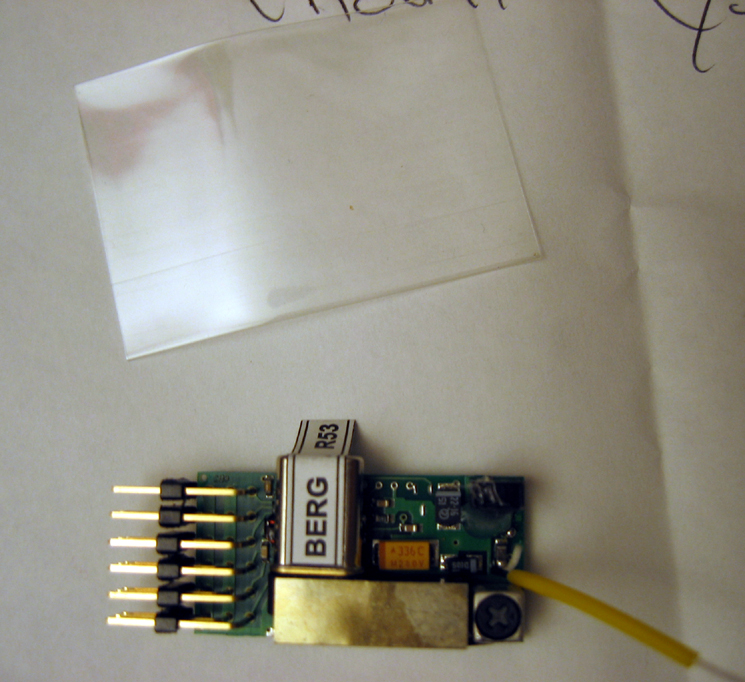

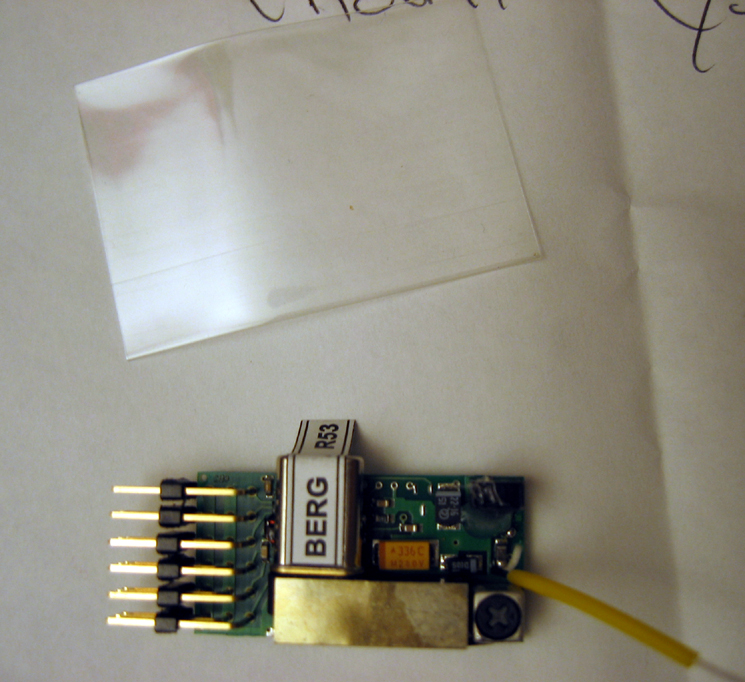

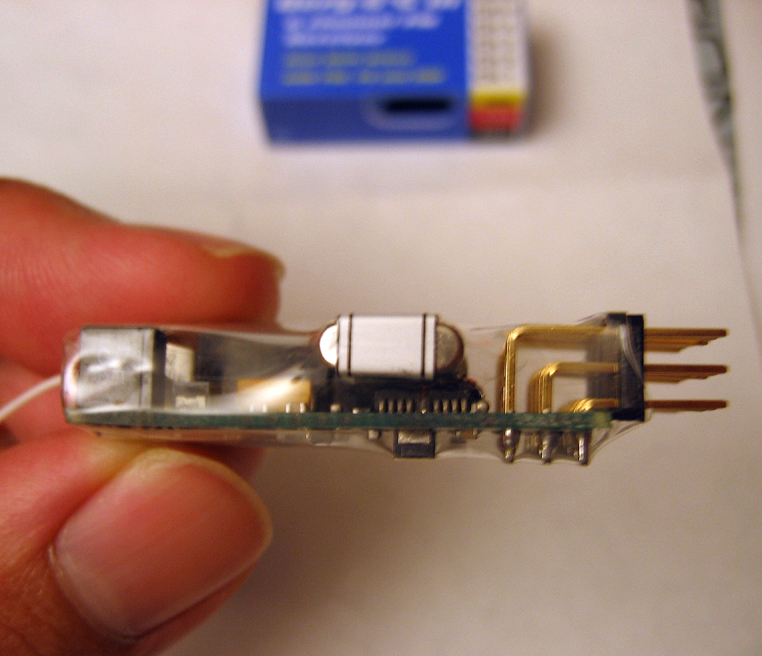

Slide a notecard under the adhesive opposite the Crystal and gently lift it off and you can open the case as seen here.

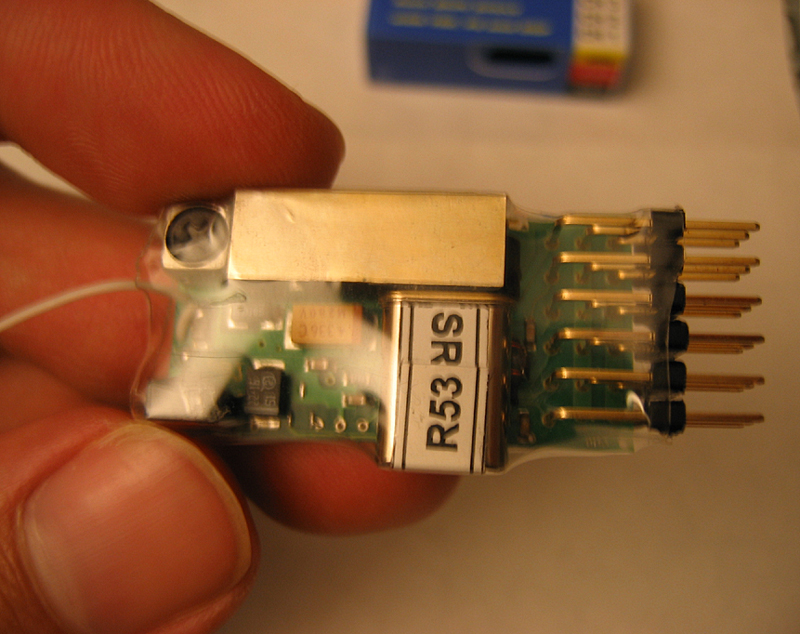

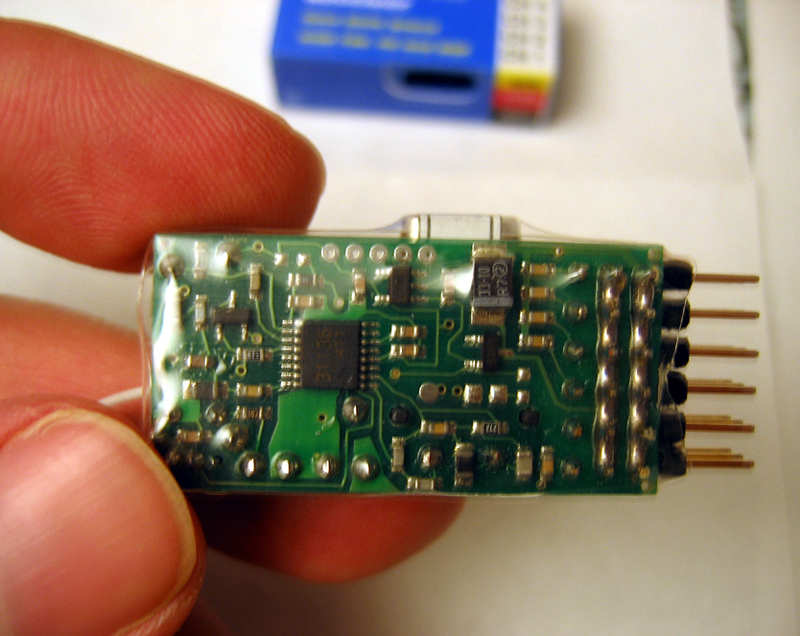

Which gives you this and saves you 3.5 grams off the total weight!

Berg is nice enough to provide some pre-cut shrink wrap along with the Receiver

Install the Crystal, then place the bare receiver inside the shrink wrap tube and gently heat with heat gun (blow dryer) or as I did you can use a Iron-on covering iron *near* but not touching it. to shrink the tubing tight around the board. I also trimmed the extra wrap off the ends a bit, mine won't need much protection from the elements anyway.

Here is a side view once it's wrapped.

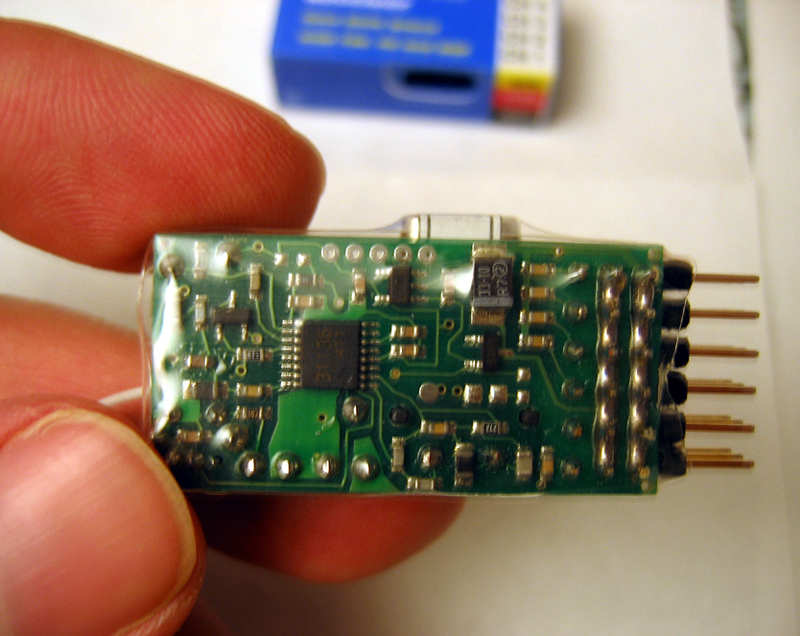

And just to be complete about it, here is the bottom of the receiver.

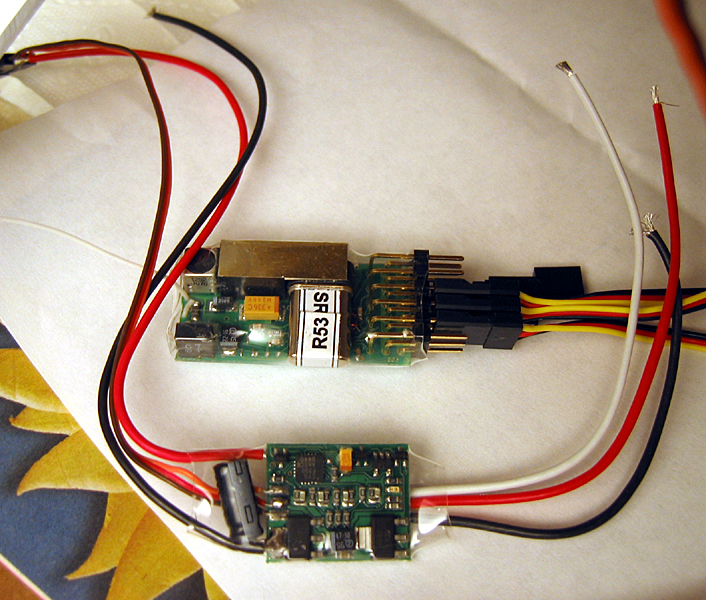

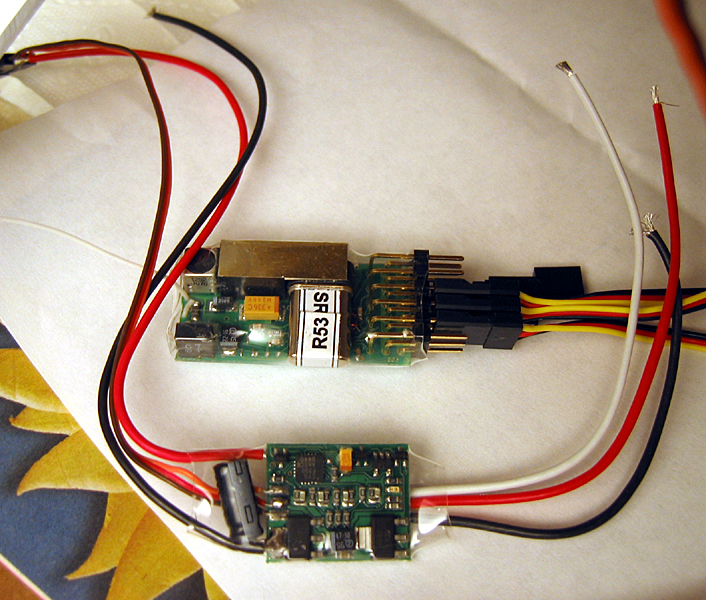

Here is the Castle Creations Phoenix 10 ESC next to the receiver. . . this little wonder is dwarfed even by the Berg Receiver. This is also shrink wrapped but that is how it comes from the manufacturer. Most of the weight of this is the wires.

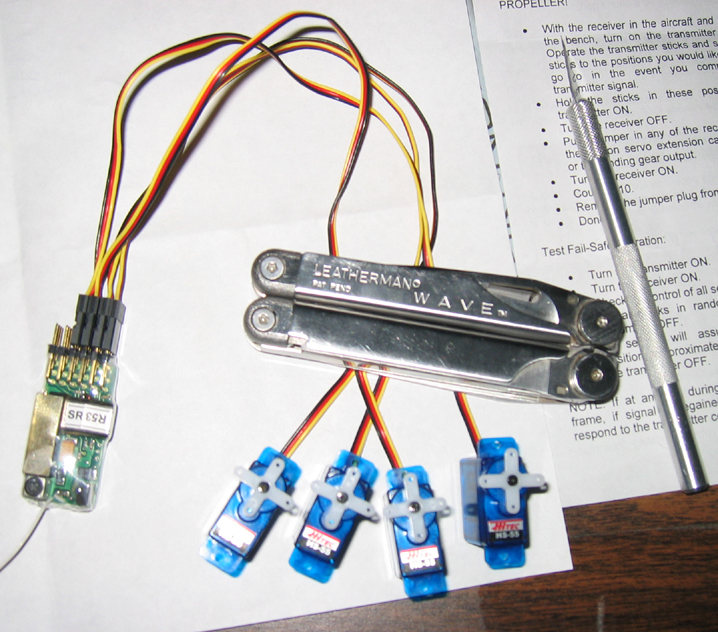

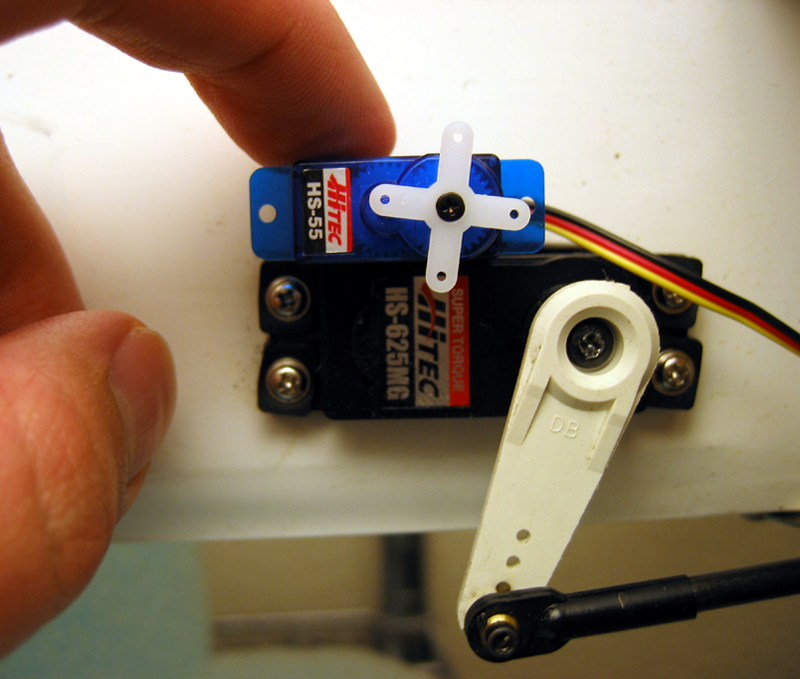

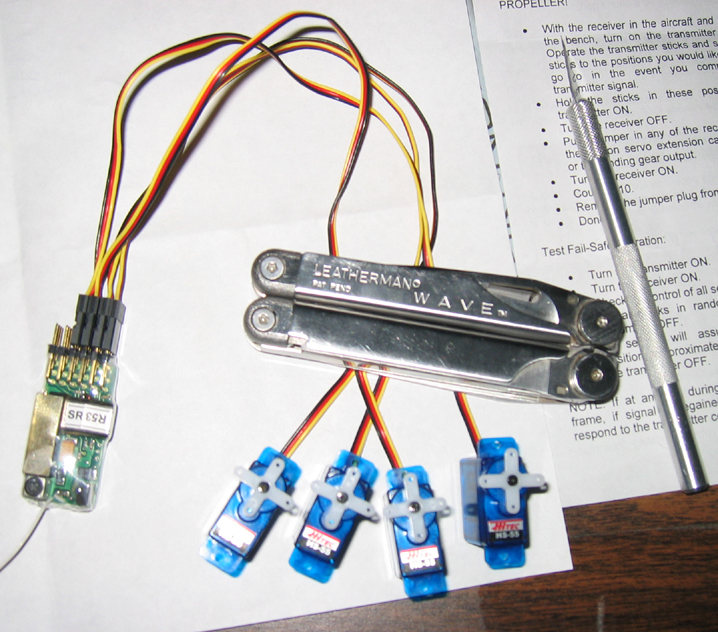

And while we are on the subject of small, here I am getting ready to test the servos and receiver. These little servos are interesting in their transparent blue cases, and they sure are tiny and cute!! :-p

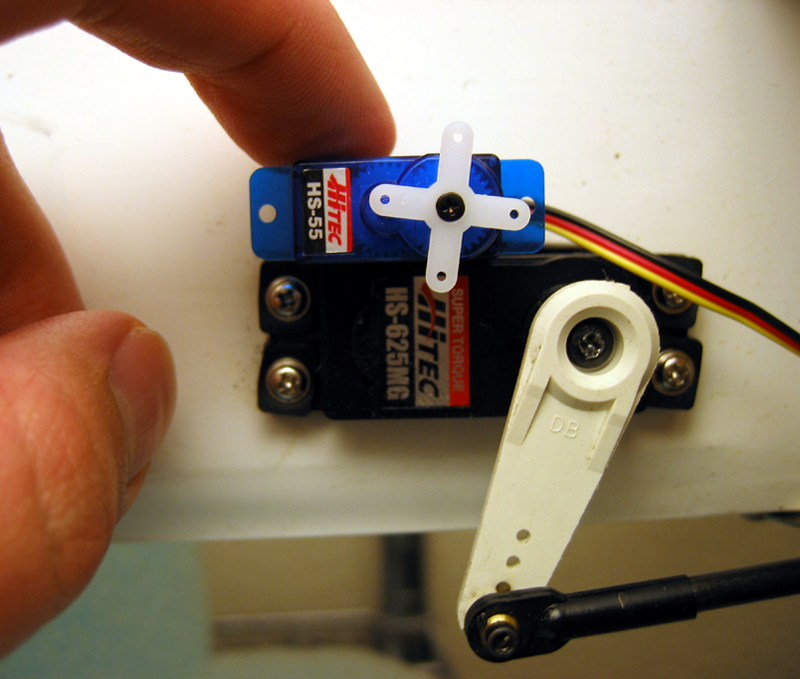

For a size comparison, here is one of the micro servos next to the HS-625MG rudder servo on my Funtana.

Berg Rx: http://www.aeromicro.com/berg6g3.htm

Phoenix 10 ESC: http://www.castlecreations.com/products/airplane/brushless/phoenix-10.html

But I got mine, as well as the the servos, from towehobbies with 20.00 off my order :-D

Through the wonders of modern debt technology, ie. a Credit Card, I should soon be in posession of the Raven from www.3dfoamy.com I am building one of these as a gift for a nephew, and one for me pretty soon.

My specs are

Plane: 3D Foamy Raven "Pro" package with Depron and G-Force wing, and Carbon Fiber Landing Gear kit.

Powerplant: AXI 2212/34

Prop: APC 11x4.7

Receiver: Berg 6*G III

Electronic speed control: Castle Creations Phoenix 10

Servos: (4) Hitec Hs-55 sub micros

two 6 inch servo extensions

Testors Spray Enamel in Dark Red 1207 , Black 1247, Gold 1244, Dark Blue 1211, Silver 1246 (mist over blue canopy), and a Testors Gold Paint Marker (I wish I bought this sooner, it works great!)

Batteries: Apogee High Discharge 830 mAh 3cell Lithium Polymer packs

Apache 2500 LiPo Safe Charger (LiPo packs are known to blow up, like. . . for real!)

All up ready to fly weight with Apogee 830 3 cell, and after a few rebuilds, and a top creations AXI stick mount is now 12.9 oz.

Some of the needed gear has already arrived, but I am still waiting on the Kit, motor, Batteries, Charger.

Here is the Berg 6* G III Receiver as it came out of the package today. These are very small, light, and jam packed with awesome features, see the link below if interested.

See, it's pretty small. . . and as I said pretty light at 13 grams. . .but. . .

Slide a notecard under the adhesive opposite the Crystal and gently lift it off and you can open the case as seen here.

Which gives you this and saves you 3.5 grams off the total weight!

Berg is nice enough to provide some pre-cut shrink wrap along with the Receiver

Install the Crystal, then place the bare receiver inside the shrink wrap tube and gently heat with heat gun (blow dryer) or as I did you can use a Iron-on covering iron *near* but not touching it. to shrink the tubing tight around the board. I also trimmed the extra wrap off the ends a bit, mine won't need much protection from the elements anyway.

Here is a side view once it's wrapped.

And just to be complete about it, here is the bottom of the receiver.

Here is the Castle Creations Phoenix 10 ESC next to the receiver. . . this little wonder is dwarfed even by the Berg Receiver. This is also shrink wrapped but that is how it comes from the manufacturer. Most of the weight of this is the wires.

And while we are on the subject of small, here I am getting ready to test the servos and receiver. These little servos are interesting in their transparent blue cases, and they sure are tiny and cute!! :-p

For a size comparison, here is one of the micro servos next to the HS-625MG rudder servo on my Funtana.

Berg Rx: http://www.aeromicro.com/berg6g3.htm

Phoenix 10 ESC: http://www.castlecreations.com/products/airplane/brushless/phoenix-10.html

But I got mine, as well as the the servos, from towehobbies with 20.00 off my order :-D

Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-Deck on January 29, 2005, 10:01:39 am

Heh, build threads are cool..... heh heh.....Looking great, keep us posted!TX-Deck out.

Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-EcoDragon on January 29, 2005, 03:28:51 pm

Looks like the Raven should ship out on monday, the rest of the gear should be here monday. . .

Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-EcoDragon on February 01, 2005, 03:46:58 am

Well, today I received the charger, the three battery packs, the AXI 2212/34 motor and motor mount. . .Now I just need the plane, Dean's Connectors, solder, and other miscellaneous gear to get started.When the box came I thought there must be another box somewhere, the box is tiny, it wouldn't even hold a VHS tape. . . but then sure enough all was there. . . I just can't seem to get used to how small all this stuff is!

Well, today I received the charger, the three battery packs, the AXI 2212/34 motor and motor mount. . .Now I just need the plane, Dean's Connectors, solder, and other miscellaneous gear to get started.When the box came I thought there must be another box somewhere, the box is tiny, it wouldn't even hold a VHS tape. . . but then sure enough all was there. . . I just can't seem to get used to how small all this stuff is!Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-Deck on February 01, 2005, 09:10:54 am

If you are really eager to get to work, you could make a plane outta that cardboard box, right?hehehe....TX-Deck out.

Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-CUDA on February 01, 2005, 08:46:40 pm

...Eco, just be thankful that you are still young and have your eyesight! Just looking at those small components for your plane had me looking for my WalMart +2.5 specials!!TX-CudaMinister of Information

Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-EcoDragon on February 02, 2005, 06:37:58 pm

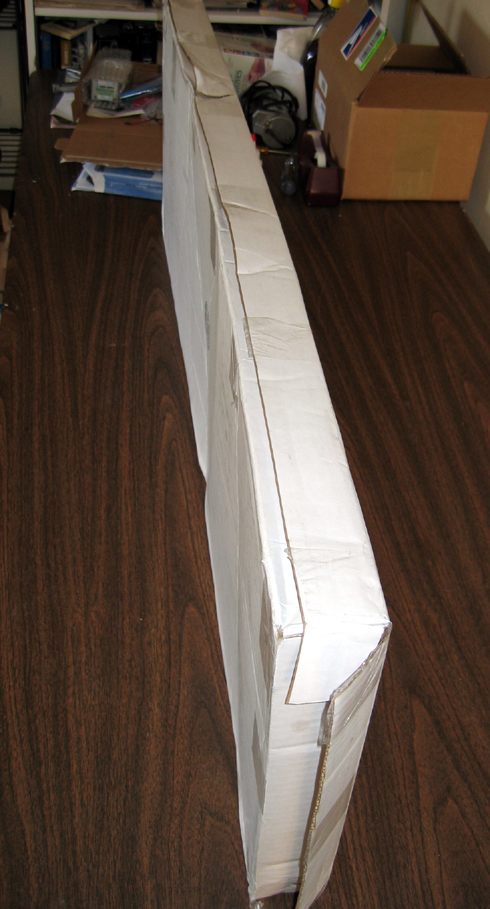

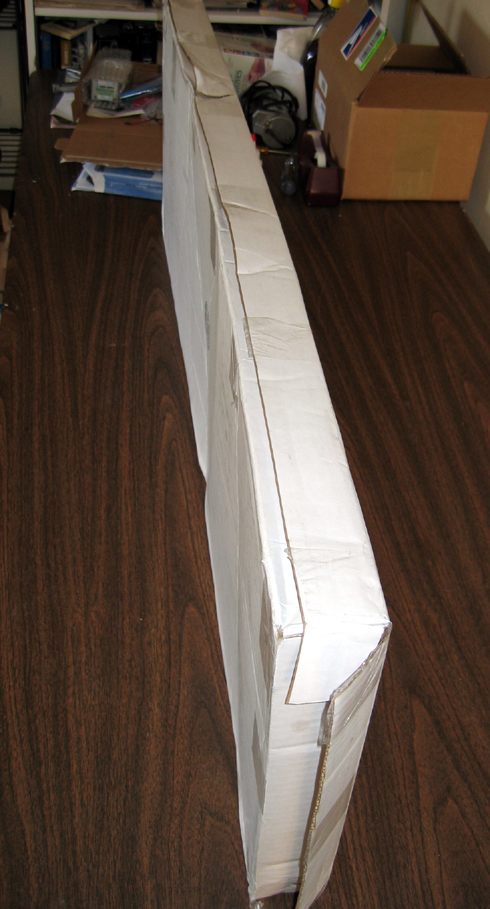

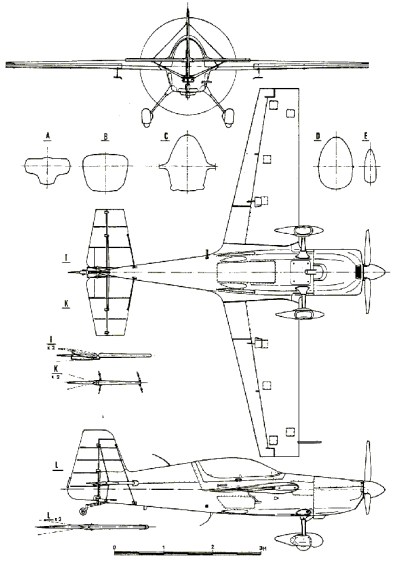

Oh . . .that's probably just my crappy camera!!! ;-)I just picked up my Raven at the front office. The USPS shipping was pretty quick for being sent on monday (today is Wed.). The box did arrive damaged, and there are portions of the depron that are crushed a little on a few of the parts, though that's not Levi's fault. It was well packaged, just not well treated by the USPS. I patched the ailerons where they were crushed and the foam skin was a creased, it's a little less nice looking, but only when you are close. It's mostly just cosmetic and should be fine as far as flying goes. Otherwise the kit looks great. . . the CF gear are pretty snazzy too! Levi did forget to include my AXI motor mount though, or perhaps it fell out of the rather large hole in the box, the carbon fiber elevator joiner rod was also missing, he said he would send them out tomorrow. This is a pretty darn nice kit for the money!EDIT: Because of the box and contents damage as well as the missing joiner rod and motor mount Levi is sending me a replacement kit, even thought I told him that this one was in good enough shape. . . nice guy! I was a bit worried when I saw the box. . . though the damage was light.

I was a bit worried when I saw the box. . . though the damage was light. Here is what's inside.

Here is what's inside. Here is the Carbon Fiber Landing Gear kit, with the wheel pants and misc. parts.

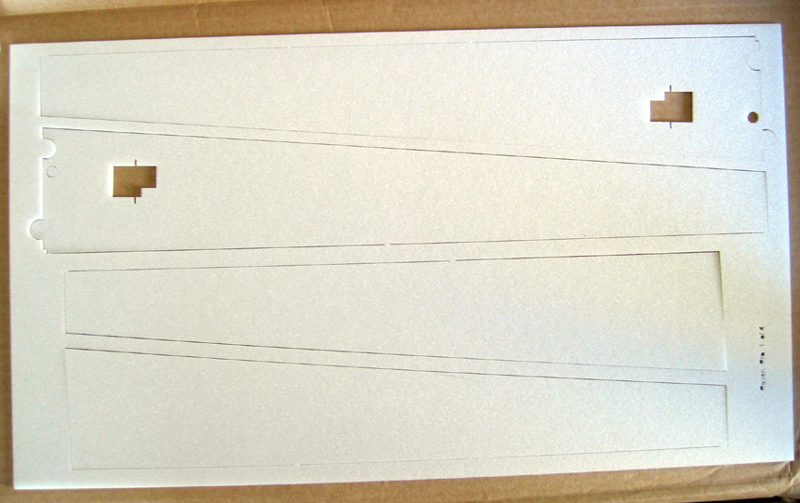

Here is the Carbon Fiber Landing Gear kit, with the wheel pants and misc. parts. Here you see the CNC Laser cut 6mm depron horizontal stabilizer and elevator halves.

Here you see the CNC Laser cut 6mm depron horizontal stabilizer and elevator halves. The Fuselage and Rudder. Jsut below this part you see the wing and fuse sides witha little damage.

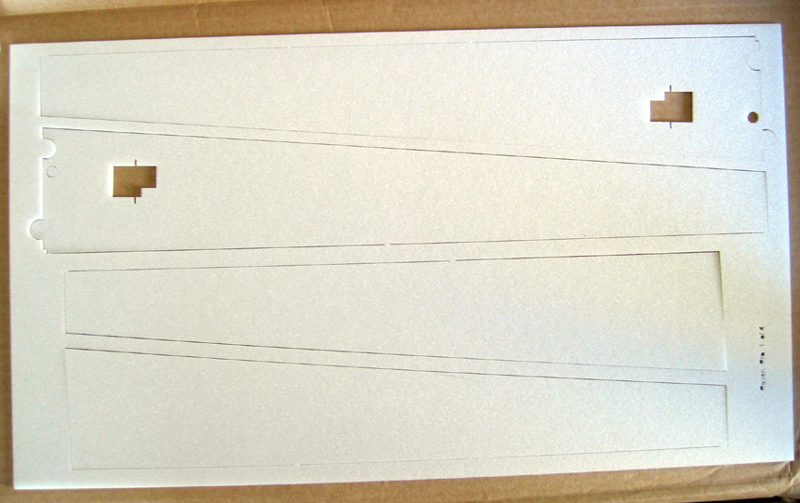

The Fuselage and Rudder. Jsut below this part you see the wing and fuse sides witha little damage. These are the wing skins which will be mounted to the main wing leading edges on top and bottom. . . you can also see the aileron servo cutouts on the bottom skins.

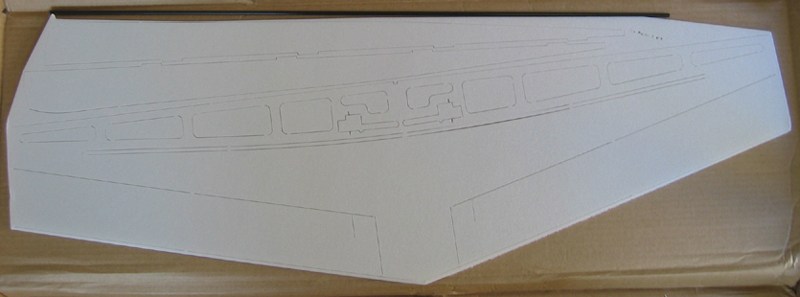

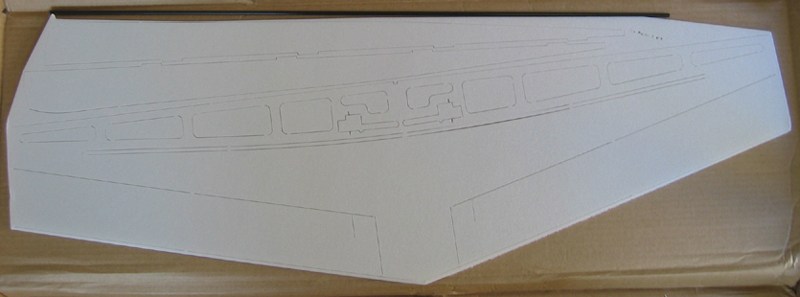

These are the wing skins which will be mounted to the main wing leading edges on top and bottom. . . you can also see the aileron servo cutouts on the bottom skins. Here is the Wing, and Fuselage sides, on top of them you can see the provided carbon fiber spar tube. You can see that this is not just a flat plate wing, this shot shows the lightening holes in the leading edge under where the skins will go, the servo wire trenches that will conceal the wiring, the large ailerons, and the precut carbon fiber spar slot. There are some compressed/folded over areas on the outboard portions of both of the ailerons from shipping damage but I patched them with some scrap foam, and they are not going to be too obvious unless your looking close.

Here is the Wing, and Fuselage sides, on top of them you can see the provided carbon fiber spar tube. You can see that this is not just a flat plate wing, this shot shows the lightening holes in the leading edge under where the skins will go, the servo wire trenches that will conceal the wiring, the large ailerons, and the precut carbon fiber spar slot. There are some compressed/folded over areas on the outboard portions of both of the ailerons from shipping damage but I patched them with some scrap foam, and they are not going to be too obvious unless your looking close.

I was a bit worried when I saw the box. . . though the damage was light.

I was a bit worried when I saw the box. . . though the damage was light. Here is what's inside.

Here is what's inside. Here is the Carbon Fiber Landing Gear kit, with the wheel pants and misc. parts.

Here is the Carbon Fiber Landing Gear kit, with the wheel pants and misc. parts. Here you see the CNC Laser cut 6mm depron horizontal stabilizer and elevator halves.

Here you see the CNC Laser cut 6mm depron horizontal stabilizer and elevator halves. The Fuselage and Rudder. Jsut below this part you see the wing and fuse sides witha little damage.

The Fuselage and Rudder. Jsut below this part you see the wing and fuse sides witha little damage. These are the wing skins which will be mounted to the main wing leading edges on top and bottom. . . you can also see the aileron servo cutouts on the bottom skins.

These are the wing skins which will be mounted to the main wing leading edges on top and bottom. . . you can also see the aileron servo cutouts on the bottom skins. Here is the Wing, and Fuselage sides, on top of them you can see the provided carbon fiber spar tube. You can see that this is not just a flat plate wing, this shot shows the lightening holes in the leading edge under where the skins will go, the servo wire trenches that will conceal the wiring, the large ailerons, and the precut carbon fiber spar slot. There are some compressed/folded over areas on the outboard portions of both of the ailerons from shipping damage but I patched them with some scrap foam, and they are not going to be too obvious unless your looking close.

Here is the Wing, and Fuselage sides, on top of them you can see the provided carbon fiber spar tube. You can see that this is not just a flat plate wing, this shot shows the lightening holes in the leading edge under where the skins will go, the servo wire trenches that will conceal the wiring, the large ailerons, and the precut carbon fiber spar slot. There are some compressed/folded over areas on the outboard portions of both of the ailerons from shipping damage but I patched them with some scrap foam, and they are not going to be too obvious unless your looking close. Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-CUDA on February 02, 2005, 11:28:09 pm

....looks good Eco. What would one of these kits with the other stuff such as servos and rcvrs/tsrs run if one of us would like to build the same thing? And what would the Helo front end add to the cost? Just curious here as I am still pumping parts into this darn box....TX-CudaMinister of Information

Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-EcoDragon on February 03, 2005, 01:46:34 am

Well, the truth is that the startup cost for the initial purchase is still as high as a more substantial R/C model. Part of this is because the motor, speed control, servos, and receiver are not really much cheaper, in fact compared to an entry level .40 size glow model these are maybe even *more*! A big part of this is the higher tech stuff in use. The powerplants, the Lithium Polymer batteries, the speed controllers, the receiver, and the servos are all very small and light yet still fully featured so this rather cutting edge stuff. Having said that the cost of operation is basically zero, and with these the airplane itself is usually a few dollars for plans built ones, up to $50-60 for the more prefabricated, larger sized models. Keep in mind though that unlike a larger balsa built up model these can be dumb thumbed into teh ground at low speeds without much issue. . . maybe the fuse breaks in half. . well. . you brought your tape and glue with you right? It's that simple. Not to mention that once you have the gear each plane you get after that will only cost you a little cash. Now, to get to the point.Here is a very complete kit sold as a package deal from FancyFoam for $329.00:http://www.fancyfoam.com/extra300l.htmWith this one you could probably stand to get another battery so you can have multiple flights, the charger will run you 45.00-50.00, and the transmitter can be a basic four channel radio which will run you as little as 90.00, though a radio with dual rates and exponential, and maybe some spoileron mixing functions is a wise idea if you want to best setup and this will be about 150.00-170.00 for the cheapest versions of these radios (these prices dont include the onboard gear, but the kit listed above does). You will also need some epoxy, some CA, and some CA kicker so the minimum total cost for the above would be:329.00+89+46+20=484Here is the all up deal for the shockflyer like ben and I have, the price is in the same range:http://www.hobby-lobby.com/shockflyer-edge.htmThe thing about these that makes them worth it for someone into RC is that you can fly everyday, it costs you nothing each time, you dont have to drive to the model airstrip, there is no noise, no cleanup, no club dues, no AMA insurance, if you crash most likely you can just use some glue and fix it. . if not, you just buy another plane for 30 bucks and off you go. Here is the one I bought: http://www.3dfoamy.com/raven.htmOh, I guess I do have two older 4 channel and two 6 channel Airtronics Vangaurd Radios. . . I would pretty much give these away to a TX member for shiping costs, though a new one would probably be a better investment in particualr if you want to do anything fancy. The variable pitch prop (tailrotor) modification is not really gonna be that pricey in itself, though to make it user friendly you will need a more capable transmitter than most 6 channels are. . .a JR 6102 or Futaba 7C would probably work allright. Also, these are custom jobs so you need to make the hollow motor shaft and linkage assembly with a suitable motor, as well as buy the tailrotor, whihc probably is pretty cheap. . and you'll need another servo which may require a greater investment in a higher cpacity speed controller to handle the extra current going to the radio gear. In the thread I posted (or did I??) are the people to ask about that. Here is the link to the RCG thread on the subject: http://www.rcgroups.com/forums/showthread.php?t=270730

Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-EcoDragon on February 03, 2005, 02:06:08 am

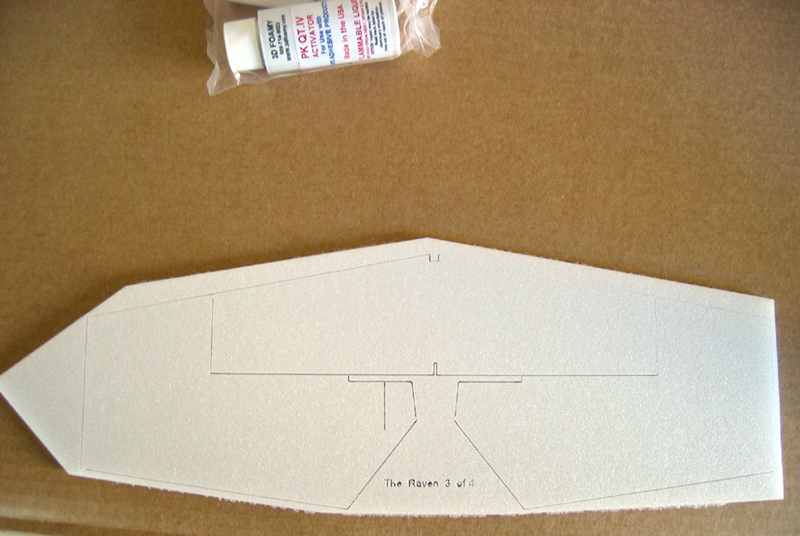

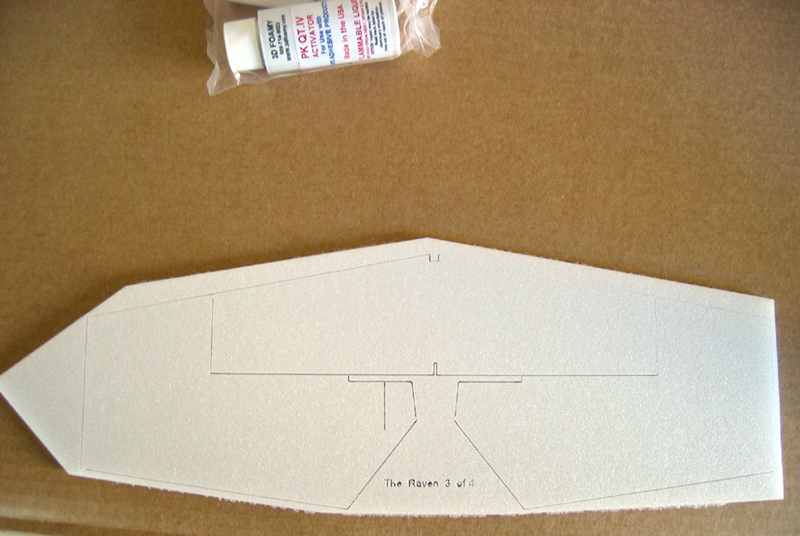

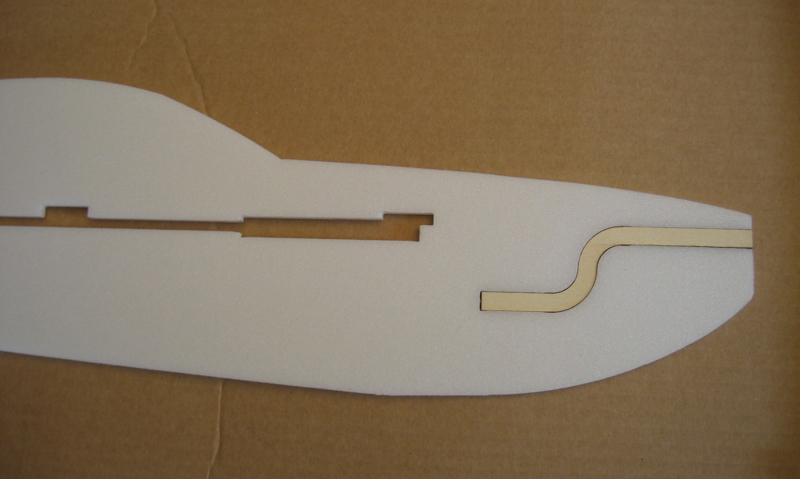

After checking the kit contents (mine was missing the custom motor mount I ordered as well as the elevator joiner rod) you need to liberate the laser cut parts from the Depron sheets using a hobby knife or razor. Here is what you will have afterwords.

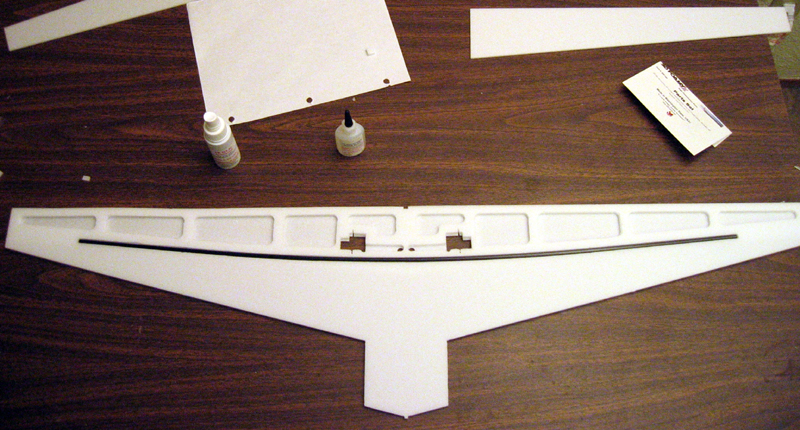

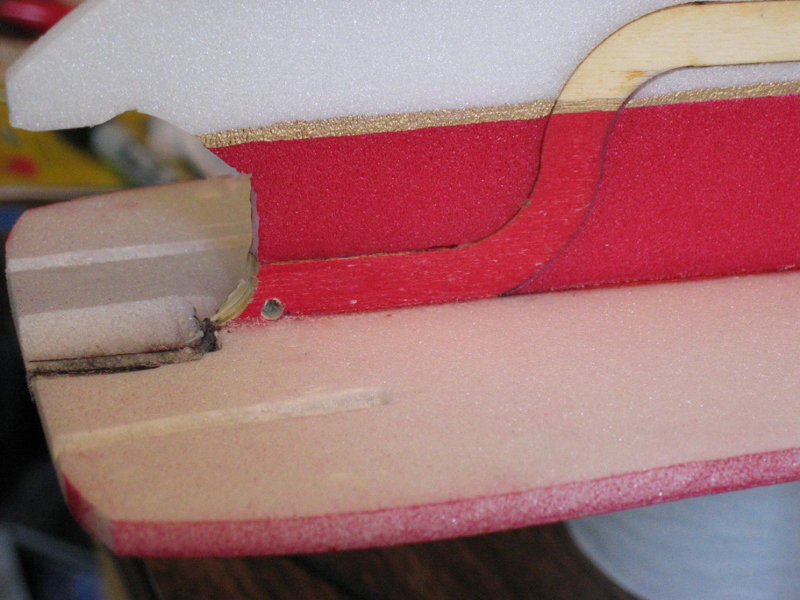

After checking the kit contents (mine was missing the custom motor mount I ordered as well as the elevator joiner rod) you need to liberate the laser cut parts from the Depron sheets using a hobby knife or razor. Here is what you will have afterwords. I skipped the next step according to the manual because I don't have the motor mount yet. . .and moved into skinning the wings. Here you see the bottom wing skins each installed on the main wing. This is done by using Foam Safe Odorless Cyanacrylate (CA) on one surface, and a foam safe kicker/accelerator on the other surface, or if you aren't sure you can work as fast as you need to for this combo you can use epoxy at a weight and time penalty. In the first picture you see these sitting just above the main wing. I used CA and kicker and had some trouble with it. The instant curing makes it harder to get everything lined up because of the cutouts in the main wing the foam can displace forward or back, and in my case the spar slot was a tad compressed after I added one of the skins, and with the glue cured there wasn't much I could do. If I was doing it again I would join up the parts without kicker and then flip the wing over to the opposite side and spray the kicker on through th holes in the wing cutouts to secure it, and then let it sit overnight so that the CA that didn't come in contact with kicker has time to cure.

I skipped the next step according to the manual because I don't have the motor mount yet. . .and moved into skinning the wings. Here you see the bottom wing skins each installed on the main wing. This is done by using Foam Safe Odorless Cyanacrylate (CA) on one surface, and a foam safe kicker/accelerator on the other surface, or if you aren't sure you can work as fast as you need to for this combo you can use epoxy at a weight and time penalty. In the first picture you see these sitting just above the main wing. I used CA and kicker and had some trouble with it. The instant curing makes it harder to get everything lined up because of the cutouts in the main wing the foam can displace forward or back, and in my case the spar slot was a tad compressed after I added one of the skins, and with the glue cured there wasn't much I could do. If I was doing it again I would join up the parts without kicker and then flip the wing over to the opposite side and spray the kicker on through th holes in the wing cutouts to secure it, and then let it sit overnight so that the CA that didn't come in contact with kicker has time to cure.Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-EcoDragon on February 03, 2005, 02:17:23 am

Once the bottom skins are on you flip the wing over and can now insert the carbon fiber spar. On this kit the spar is kept under tension buy it being flexed forward as you can see. Once you verify the spar will seat correctly in the spar cutout prepare some 5-30 minunte epoxy and use this to secure the spar in the wing slot. Ensure that the spar is pressed flush in the groove, I like to weight the assemply a little to be certain things are where I want them, wipe off any excess with denatured alchohol treated cloth, and let the epoxy cure. Be careful to use the minimal amounts of glue in everything that you do on these, this is a prime example.

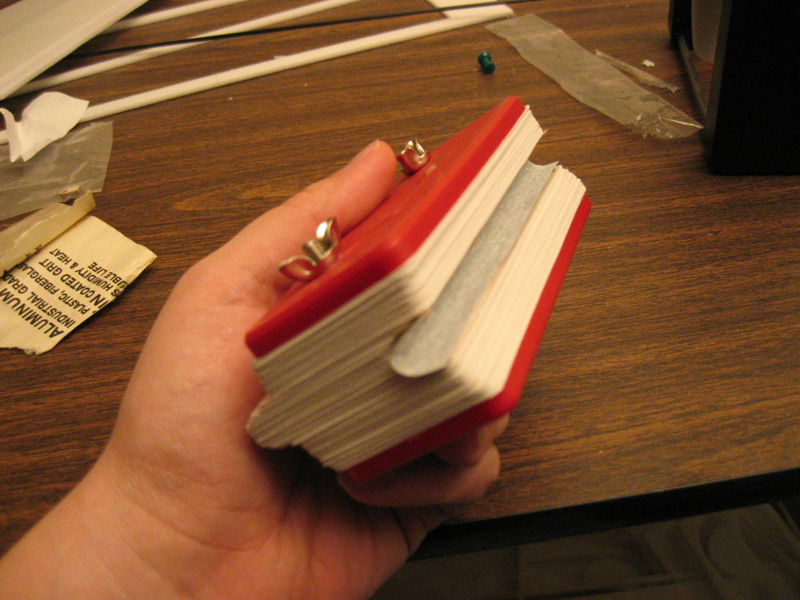

Once the bottom skins are on you flip the wing over and can now insert the carbon fiber spar. On this kit the spar is kept under tension buy it being flexed forward as you can see. Once you verify the spar will seat correctly in the spar cutout prepare some 5-30 minunte epoxy and use this to secure the spar in the wing slot. Ensure that the spar is pressed flush in the groove, I like to weight the assemply a little to be certain things are where I want them, wipe off any excess with denatured alchohol treated cloth, and let the epoxy cure. Be careful to use the minimal amounts of glue in everything that you do on these, this is a prime example.  Here is my fancy shmancy method for weighing down the spar while the epoxy cures.

Here is my fancy shmancy method for weighing down the spar while the epoxy cures. Once the epoxy has cured it is time to use CA and kicker to glue the top surface skins over the wings leading edge, just like was done on the underside of the wing leading edge. The top surface skins don't join in the middle as teh bottom ones did, these should be lined up flush witht eh leading edge and wing tips as seen above.

Once the epoxy has cured it is time to use CA and kicker to glue the top surface skins over the wings leading edge, just like was done on the underside of the wing leading edge. The top surface skins don't join in the middle as teh bottom ones did, these should be lined up flush witht eh leading edge and wing tips as seen above.Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-Deck on February 03, 2005, 08:21:12 am

A Leatherman, some scotch tape, and some funky purple windex.... I love it!TX-Deck out.

Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-EcoDragon on February 06, 2005, 10:06:34 pm

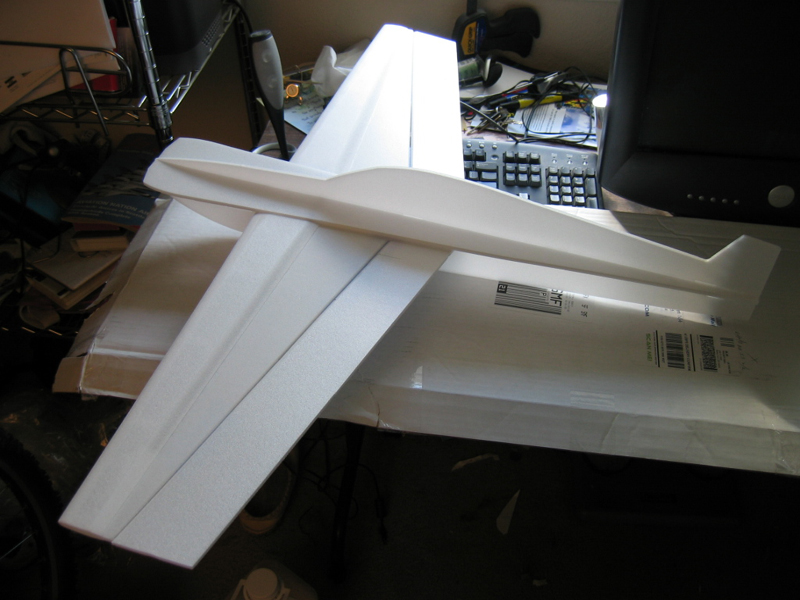

Here is the fully built main wing before sanding the Leading edge and before sanding the trailing edge of the top and bottom skins.

Here is the fully built main wing before sanding the Leading edge and before sanding the trailing edge of the top and bottom skins.  Here is a Great Planes Controur Sander loaded with 80 Grit sticky-backed sandpaper that I shaped as you see here, this will be used to sand the leading edge of the wing into an airfoiled shape.

Here is a Great Planes Controur Sander loaded with 80 Grit sticky-backed sandpaper that I shaped as you see here, this will be used to sand the leading edge of the wing into an airfoiled shape. Here is the wing after sanding the LE.Note that I also beveled all leading edges of the control surfaces, and the trailing edges where they meet up.

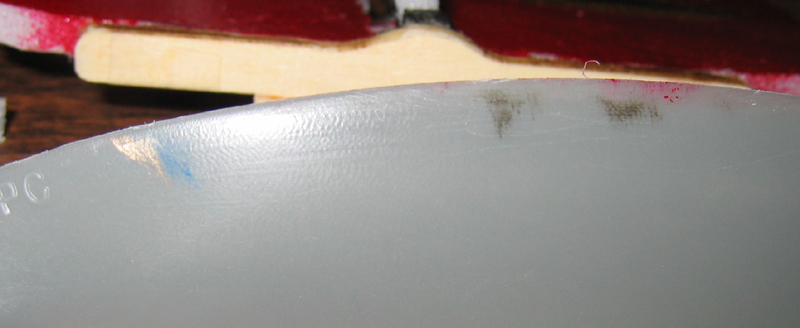

Here is the wing after sanding the LE.Note that I also beveled all leading edges of the control surfaces, and the trailing edges where they meet up. Here is how you prepare the wing to have the wing skin trailing edges blended into the main wing. (optional, and sanding may actually reduce lift and drag somewhat, I did a 50/50 blend, I didn't leave it as it, and I didn't blend it cleanly into the main wing.)Once you have this done use a sanding block with 80 grit sandpaper to smooth the trailing edge a bit. Do this on all four wing skins. The Masking Tape should help protect teh areas of the wing you dont want sanded. Here is a tip: I discovered after the wing was painted that the sanded foam, and the unsanded foam hold paint differently and you can see this in the finished product, though it's not bad, for htose of you who spend weeks building something like a foamy then you might want to consider a light sanding to the wing skins between the bevels at teh LE and TE of the skins to give them a more uniform appearance.

Here is how you prepare the wing to have the wing skin trailing edges blended into the main wing. (optional, and sanding may actually reduce lift and drag somewhat, I did a 50/50 blend, I didn't leave it as it, and I didn't blend it cleanly into the main wing.)Once you have this done use a sanding block with 80 grit sandpaper to smooth the trailing edge a bit. Do this on all four wing skins. The Masking Tape should help protect teh areas of the wing you dont want sanded. Here is a tip: I discovered after the wing was painted that the sanded foam, and the unsanded foam hold paint differently and you can see this in the finished product, though it's not bad, for htose of you who spend weeks building something like a foamy then you might want to consider a light sanding to the wing skins between the bevels at teh LE and TE of the skins to give them a more uniform appearance. Here is what mine looks like all done.

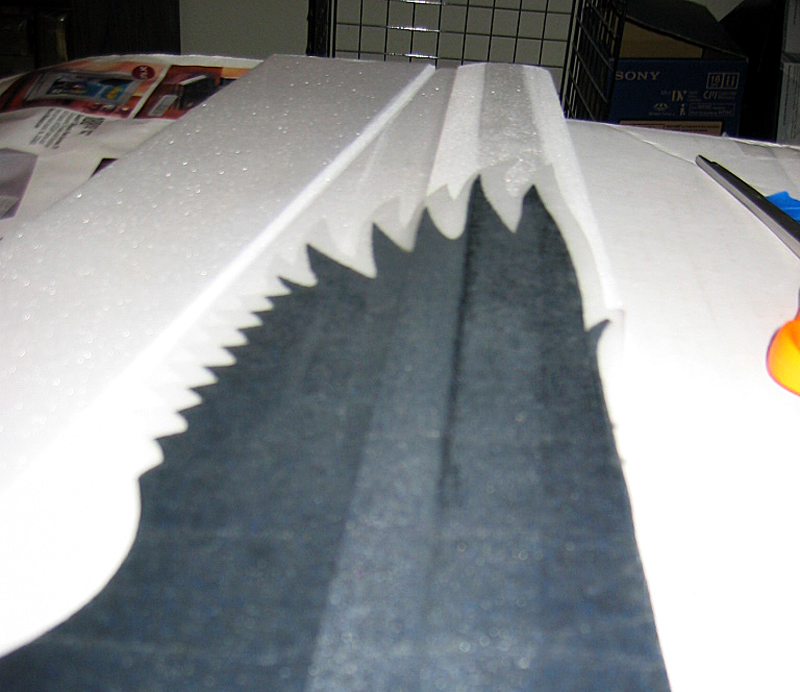

Here is what mine looks like all done. Here is the Wing and Ailerons mated up and ready to be painted. I have been trying ot figure out how to paint th rather tricky Raven Graphic onto the aircraft, I wasn't really sure how I was going to do it, but I think I have found a way!

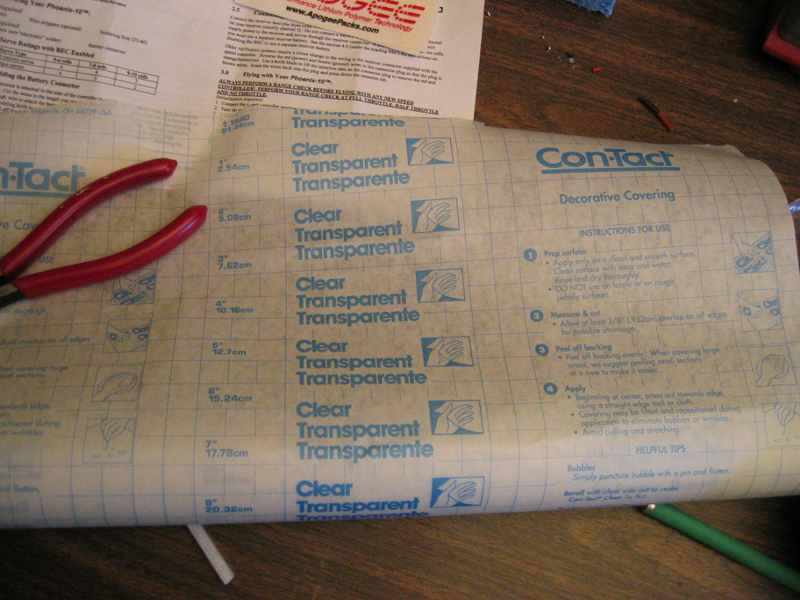

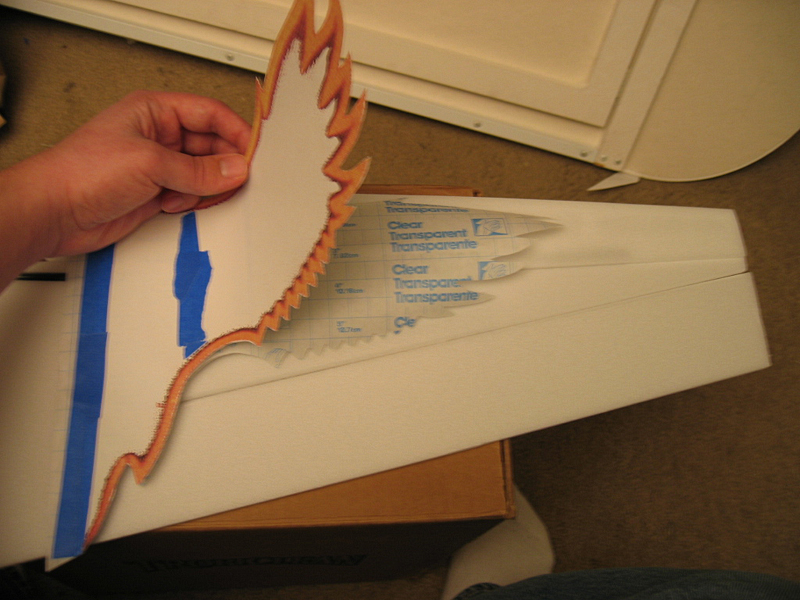

Here is the Wing and Ailerons mated up and ready to be painted. I have been trying ot figure out how to paint th rather tricky Raven Graphic onto the aircraft, I wasn't really sure how I was going to do it, but I think I have found a way! Here is some contact paper I found at the hardware store. It is low-tack, transparent, semi flexible (hope this works). I am experimenting here, but I did a test run and found that the contact paper didn't seem to damage the foam when removed, and didn't allow for any more bleeding than did my Blue Painters Masking tape. . .wish me luck.

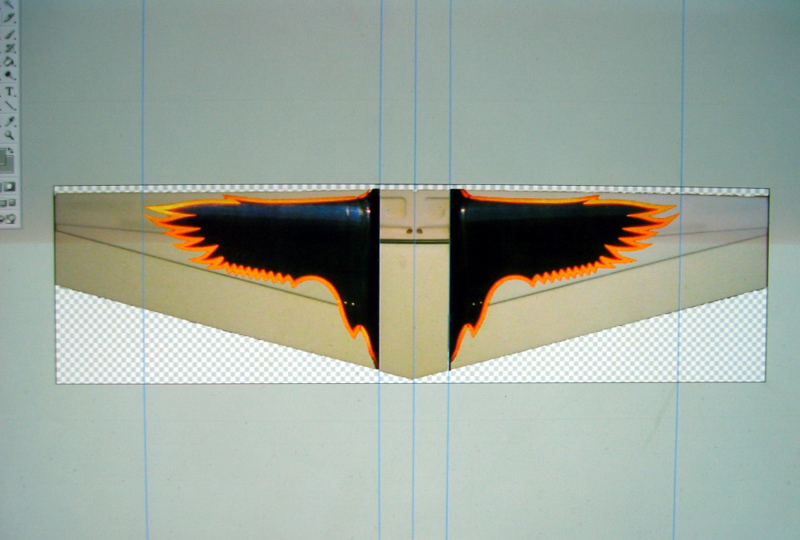

Here is some contact paper I found at the hardware store. It is low-tack, transparent, semi flexible (hope this works). I am experimenting here, but I did a test run and found that the contact paper didn't seem to damage the foam when removed, and didn't allow for any more bleeding than did my Blue Painters Masking tape. . .wish me luck. I used the photo before last to make the stencil mask for getting a true to life Raven graphic by taking the photo of the wing and setting it at 1:1 scale, and then resizing a photo of the full scale raven untill I had what I wanted.

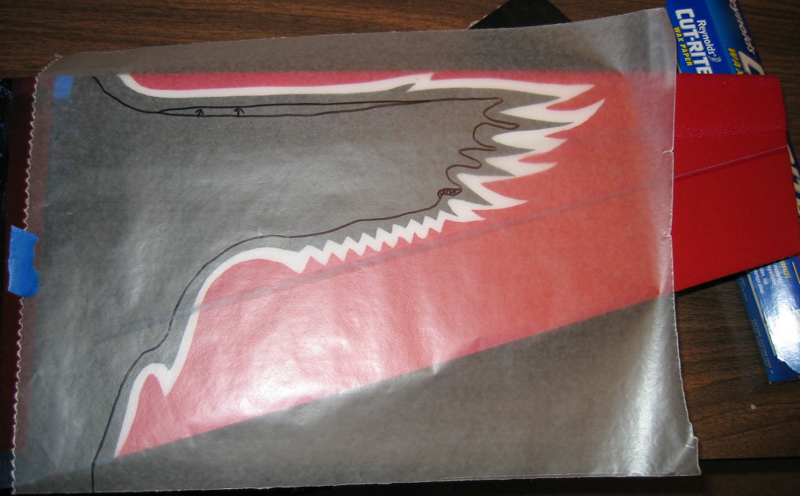

I used the photo before last to make the stencil mask for getting a true to life Raven graphic by taking the photo of the wing and setting it at 1:1 scale, and then resizing a photo of the full scale raven untill I had what I wanted. next I excised the blue/black portion of the Raven graphic to save on ink, and was then ready to output the Raven Graphic tiles on my InkJet. I split the image you see here in two so that I could print it at full size from my PC.

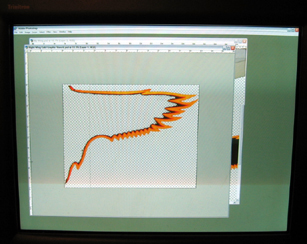

next I excised the blue/black portion of the Raven graphic to save on ink, and was then ready to output the Raven Graphic tiles on my InkJet. I split the image you see here in two so that I could print it at full size from my PC. Then I lined up the two halves of the raven graphic and taped them together. Once they were lined up and joined I taped them to the contact paper.

Then I lined up the two halves of the raven graphic and taped them together. Once they were lined up and joined I taped them to the contact paper. I laid the above assembly on a mirror and used a fresh Xacto knife and traced around the edges of the raven graphic, pressing hard enough to cut down to the glass. Once done you are left with the contact paper mask cut just like the full scale Raven!

I laid the above assembly on a mirror and used a fresh Xacto knife and traced around the edges of the raven graphic, pressing hard enough to cut down to the glass. Once done you are left with the contact paper mask cut just like the full scale Raven!Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-EcoDragon on February 06, 2005, 10:21:36 pm

The handy thing about this method is that I make one session of cutting and I get two masks. . here is the outer part of the contact paper that I will use in conjunction ith a smaller inner mask to spray paint the gold detail.Not shown in the pictures but required for what I am doing is to cut two mroe raven wing graphic panels by tracing with an xacto the inner line of the gold trim in the inkjet output. this gives me what I need to paint all three colors and mask the others.

The handy thing about this method is that I make one session of cutting and I get two masks. . here is the outer part of the contact paper that I will use in conjunction ith a smaller inner mask to spray paint the gold detail.Not shown in the pictures but required for what I am doing is to cut two mroe raven wing graphic panels by tracing with an xacto the inner line of the gold trim in the inkjet output. this gives me what I need to paint all three colors and mask the others. Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-EcoDragon on February 07, 2005, 07:04:52 pm

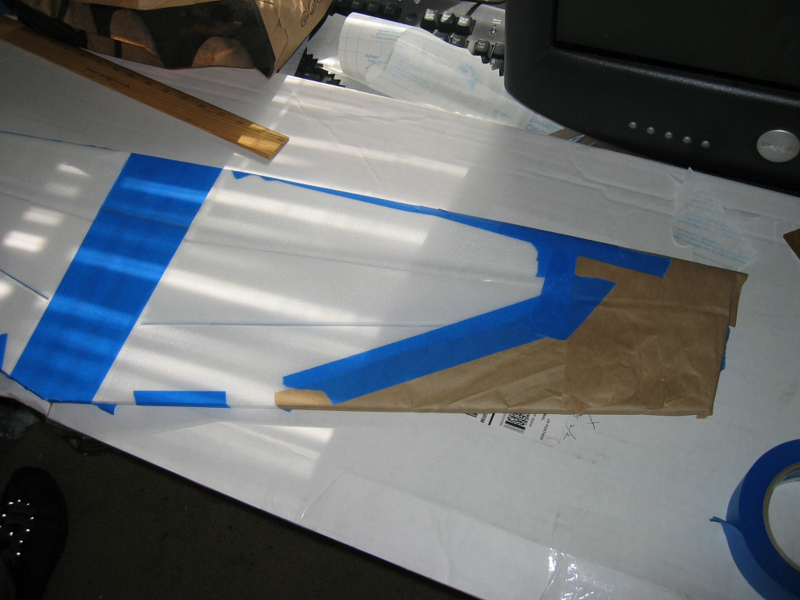

Here is the wing, fuse and side rails installed as a test run in prep for masking.

Here is the wing, fuse and side rails installed as a test run in prep for masking.  Wing masked for inner Raven Graphic with the transparent stencil and masking tape all ready to pant.

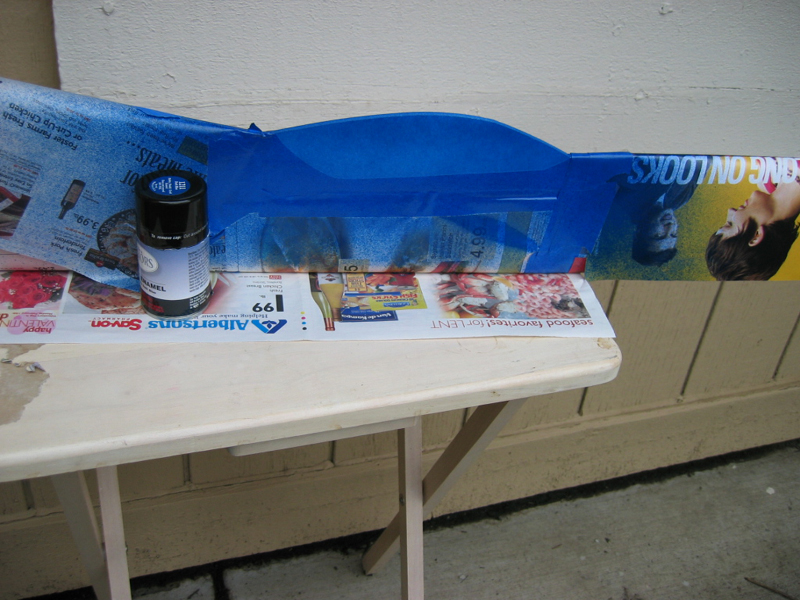

Wing masked for inner Raven Graphic with the transparent stencil and masking tape all ready to pant. First Wing Coat. I wanted the blue to fill is some of the holes that the foam has, usually you can see these through the light coats of paint, so I thought this might give me a blue black look when the sun hit the plane. . .just like the full scale Raven.

First Wing Coat. I wanted the blue to fill is some of the holes that the foam has, usually you can see these through the light coats of paint, so I thought this might give me a blue black look when the sun hit the plane. . .just like the full scale Raven. Here is the second coat of paint, this time in black. . .obviously.

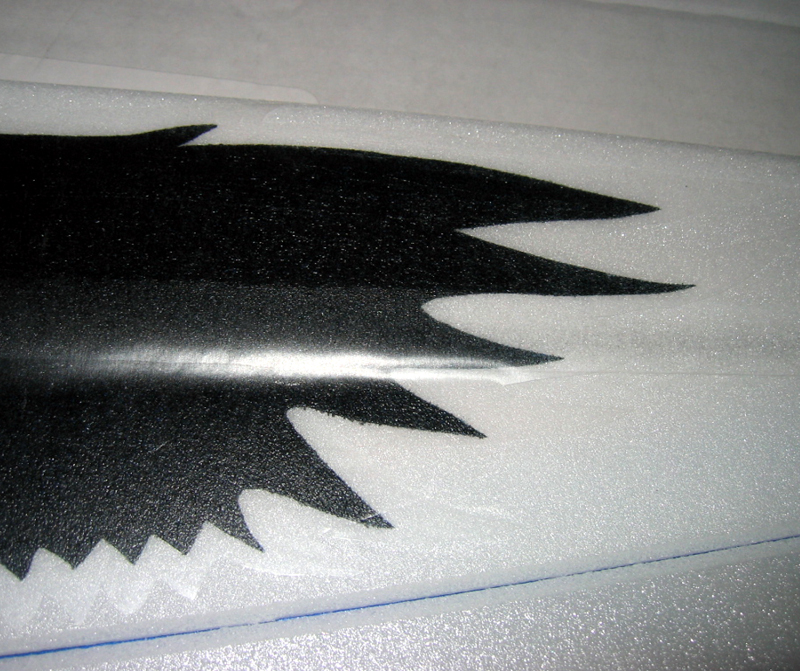

Here is the second coat of paint, this time in black. . .obviously. I did another coat and let it dry. . here is the finished inner Raven graphic as I remove the contact "paper" (more like vinyl) from the wing. Note that the center section, is masked off to save on some weight. As it is I will probably have a pretty heavy plane when all my painting is done. . . Oh well, that's why I bought 830 mAh batteries instead of 1200-1500 mAh packs! Next I will be doing the red coats, and lastly the gold.

I did another coat and let it dry. . here is the finished inner Raven graphic as I remove the contact "paper" (more like vinyl) from the wing. Note that the center section, is masked off to save on some weight. As it is I will probably have a pretty heavy plane when all my painting is done. . . Oh well, that's why I bought 830 mAh batteries instead of 1200-1500 mAh packs! Next I will be doing the red coats, and lastly the gold.Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-EcoDragon on February 07, 2005, 08:45:11 pm

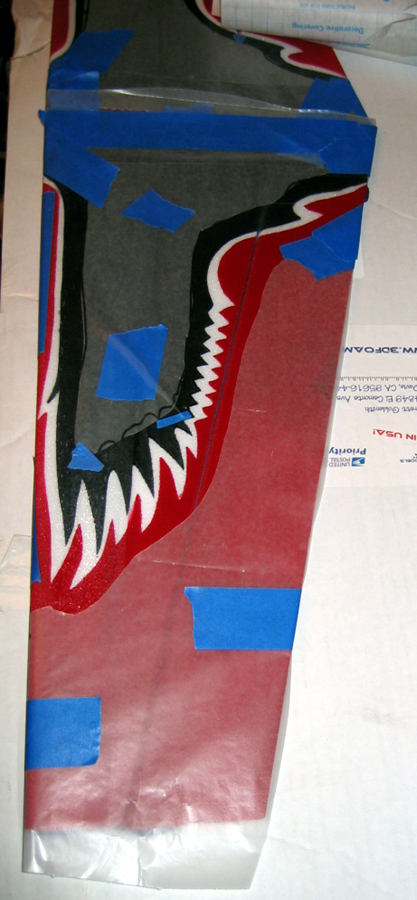

Here is the contact paper stencil mask applied to the right wing in prep for the red coat. This will mask off the black raven graphic, as well as the currently white border which will be be painted gold in teh next painting session. The neat thing about the way I am doing it is that I have enough masks that I don't need to have any paint layers overlapping, they sit right next to each other, just touching, but no layering of colors is needed.

Here is the contact paper stencil mask applied to the right wing in prep for the red coat. This will mask off the black raven graphic, as well as the currently white border which will be be painted gold in teh next painting session. The neat thing about the way I am doing it is that I have enough masks that I don't need to have any paint layers overlapping, they sit right next to each other, just touching, but no layering of colors is needed. Another angle, I know the stencil is hard to see since it's clear. . . but as you see here that makes this job much more precise. Time to paint it!

Another angle, I know the stencil is hard to see since it's clear. . . but as you see here that makes this job much more precise. Time to paint it! Here is the first coat. Here it is a little easier to see where the stencil mask is as it reacts to the paint differently than the foam does.

Here is the first coat. Here it is a little easier to see where the stencil mask is as it reacts to the paint differently than the foam does. Another view.Since it looks like this Con-Tact Paper works and since I used the yard of it that I bought I need to head out to ACE again before doing the fuselage!

Another view.Since it looks like this Con-Tact Paper works and since I used the yard of it that I bought I need to head out to ACE again before doing the fuselage! Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-Deck on February 08, 2005, 08:18:18 am

Are you back yet? I'm eager to see what happens next... ;)TX-Deck out.

Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-EcoDragon on February 08, 2005, 03:31:38 pm

Well, after drying overnight I peeled the contact paper off. It did take a little of the black paint with it, but nothing too bad. Perhaps leaving it in the sun for a few minutes, or simply not letting it sit overnight might have helped. From now on I will place a sheet of wax paper under the center parts of the contact paper to keep it from lifting much of the paint. Note that the center section of the wing, in between the skins and ailerons is masked off so it is still bare foam, it's just covered in masking tape! I also added all the control surfaces to the wings/stabs using CA hinges. I found the foam flexed a bit at teh point where the control horns meet the aileron so I might suggest that one hinge be placed just inboard of the control horn mounting location to keep the surface from getting tweaked under load.

Well, after drying overnight I peeled the contact paper off. It did take a little of the black paint with it, but nothing too bad. Perhaps leaving it in the sun for a few minutes, or simply not letting it sit overnight might have helped. From now on I will place a sheet of wax paper under the center parts of the contact paper to keep it from lifting much of the paint. Note that the center section of the wing, in between the skins and ailerons is masked off so it is still bare foam, it's just covered in masking tape! I also added all the control surfaces to the wings/stabs using CA hinges. I found the foam flexed a bit at teh point where the control horns meet the aileron so I might suggest that one hinge be placed just inboard of the control horn mounting location to keep the surface from getting tweaked under load.  I also did the horizontal stab and elevator halves which you can see here, as well as the Apogee 830s that I just added Dean's Micro connectors to.. Next will come the gold layer. . . other than that I am waiting on my AXI motor mount to arrive to continue. I may just have to get one made. . .

I also did the horizontal stab and elevator halves which you can see here, as well as the Apogee 830s that I just added Dean's Micro connectors to.. Next will come the gold layer. . . other than that I am waiting on my AXI motor mount to arrive to continue. I may just have to get one made. . .Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-EcoDragon on February 09, 2005, 12:07:58 am

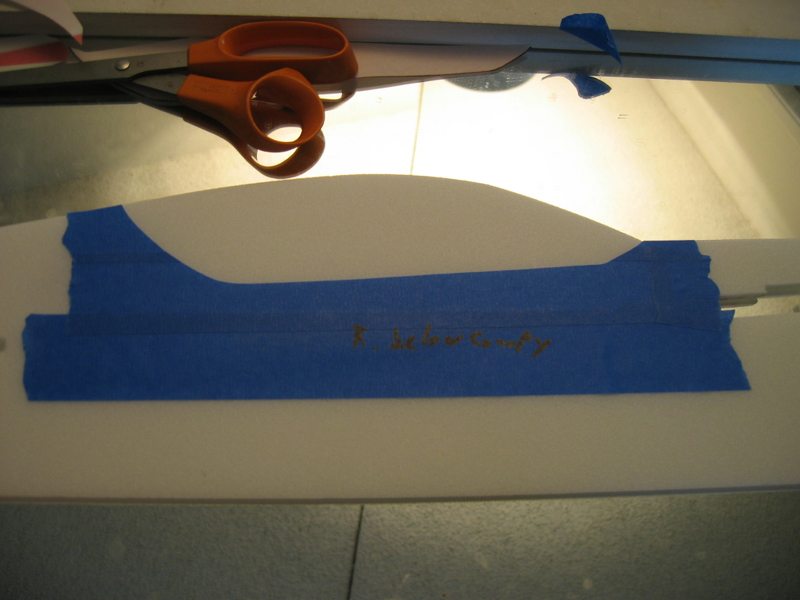

I decided to cut out some wax paper to place in the center portions of the contact paper so i could minimize the paint removing that it did on the previous runs. I just drew a rough little line with a sharpie and then cut it out. This is to protect the black of the raven graphic.

I decided to cut out some wax paper to place in the center portions of the contact paper so i could minimize the paint removing that it did on the previous runs. I just drew a rough little line with a sharpie and then cut it out. This is to protect the black of the raven graphic. This section will protect the red of the wing.

This section will protect the red of the wing. I placed the stencil over the wax paper, and then added the gold paint. The Leading edge was a real pain becasue the contact paper wouldnt stick to the curved area. . .I just sprayed the paint on an angle so that it was less prone to overspray under the mask.

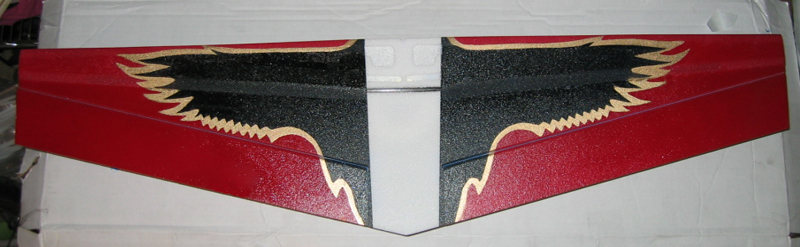

I placed the stencil over the wax paper, and then added the gold paint. The Leading edge was a real pain becasue the contact paper wouldnt stick to the curved area. . .I just sprayed the paint on an angle so that it was less prone to overspray under the mask. Here is the finished wing after touching it up a bit. Looks pretty good if I do say so myself!!

Here is the finished wing after touching it up a bit. Looks pretty good if I do say so myself!!Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-EcoDragon on February 11, 2005, 02:32:41 am

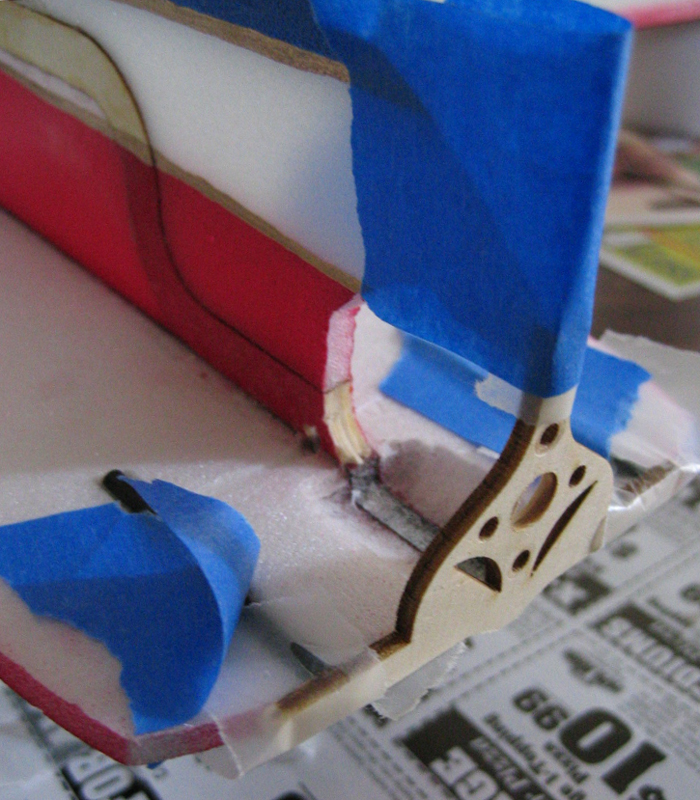

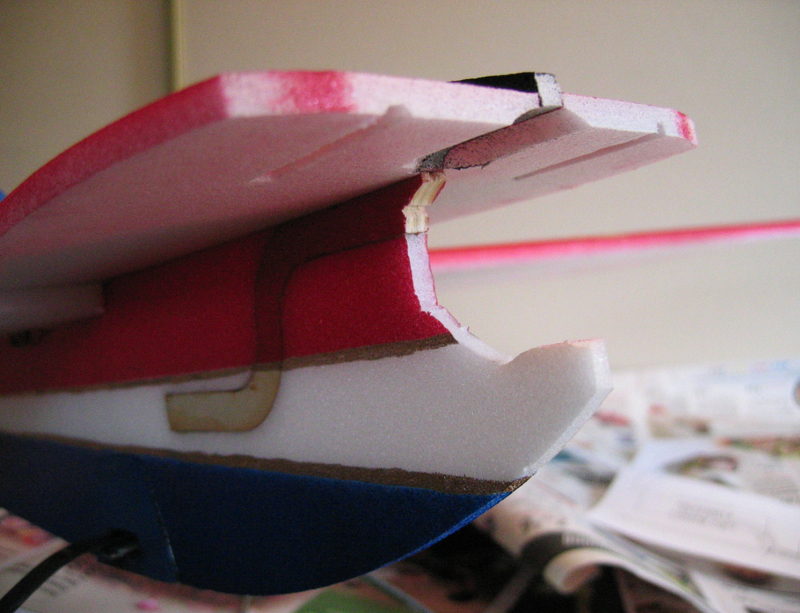

I have moved on from the Contact paper technique. . now it's masking tape laid out in sheets on wax paper. . . a little more conventional, and it sticks better on countours and hopefully wont pull as much paint off. Above you see the masking tape as cut for top of the fuse, this mask is for the red, there is an outer trim cut here which I will leave in the next painting session, and just peel the center section out to do the black next, while masking off everything that is red. As before I have the outlines of the wax paper masks that will fit like a puzzle piece over the red paint. . .hopefully it wont remove any paint when I peel it back off.

I have moved on from the Contact paper technique. . now it's masking tape laid out in sheets on wax paper. . . a little more conventional, and it sticks better on countours and hopefully wont pull as much paint off. Above you see the masking tape as cut for top of the fuse, this mask is for the red, there is an outer trim cut here which I will leave in the next painting session, and just peel the center section out to do the black next, while masking off everything that is red. As before I have the outlines of the wax paper masks that will fit like a puzzle piece over the red paint. . .hopefully it wont remove any paint when I peel it back off. fuse tops 1,2,3,4(note that the angle I shot these at makes the fuse sides not look symmetrical . but they are.)Pic 1) This pic shows the fuse after applying the red coat.Pic 2) After the red paint dried I added the red mask (here seen in blue), and then peeled the gold trim mask out from between the two masks in prep to paint the gold layer.Pic 3) This is the fuse top after applying the gold coat. I removed the innermost section of the mask leaving the area that will be painted black exposed, and reapplied the thin masking layer where the gold was painted (after it fully dried). Now it's ready for the black!!Pic 4) Here is the finished paint on the fuse side tops. The masking tape does bleed more than the contact paper did, but part of that is that I had to reuse the tape stencils once and the removal and reapplication was a little tricky so the tape was not as sticky and crisp as it could have been, I used a hobby knife to etch the black bleed through areas off of the gold as the black paint had not fully dried when I removed the masks. Overall I am pretty happy with this! This is gonna be one sweet looking foamy. . . I just hope it's not 20 oz.!!Next I have to paint the side of the fuselage, and then there is not much left other than landing gear, radio and engine isntallation. . and I am still waiting on a motor mount. . . I bought some carbon tube that works in place of the elevator joiner, I attempted to hand cut (w/Xacto!) a firewall type motor mount, but it ended up being pretty much a waste of time and balsa. I am hoping the motor mount shows up tomorrow. . . it's high time I fly this thing!!

fuse tops 1,2,3,4(note that the angle I shot these at makes the fuse sides not look symmetrical . but they are.)Pic 1) This pic shows the fuse after applying the red coat.Pic 2) After the red paint dried I added the red mask (here seen in blue), and then peeled the gold trim mask out from between the two masks in prep to paint the gold layer.Pic 3) This is the fuse top after applying the gold coat. I removed the innermost section of the mask leaving the area that will be painted black exposed, and reapplied the thin masking layer where the gold was painted (after it fully dried). Now it's ready for the black!!Pic 4) Here is the finished paint on the fuse side tops. The masking tape does bleed more than the contact paper did, but part of that is that I had to reuse the tape stencils once and the removal and reapplication was a little tricky so the tape was not as sticky and crisp as it could have been, I used a hobby knife to etch the black bleed through areas off of the gold as the black paint had not fully dried when I removed the masks. Overall I am pretty happy with this! This is gonna be one sweet looking foamy. . . I just hope it's not 20 oz.!!Next I have to paint the side of the fuselage, and then there is not much left other than landing gear, radio and engine isntallation. . and I am still waiting on a motor mount. . . I bought some carbon tube that works in place of the elevator joiner, I attempted to hand cut (w/Xacto!) a firewall type motor mount, but it ended up being pretty much a waste of time and balsa. I am hoping the motor mount shows up tomorrow. . . it's high time I fly this thing!!Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-EcoDragon on February 11, 2005, 07:04:04 pm

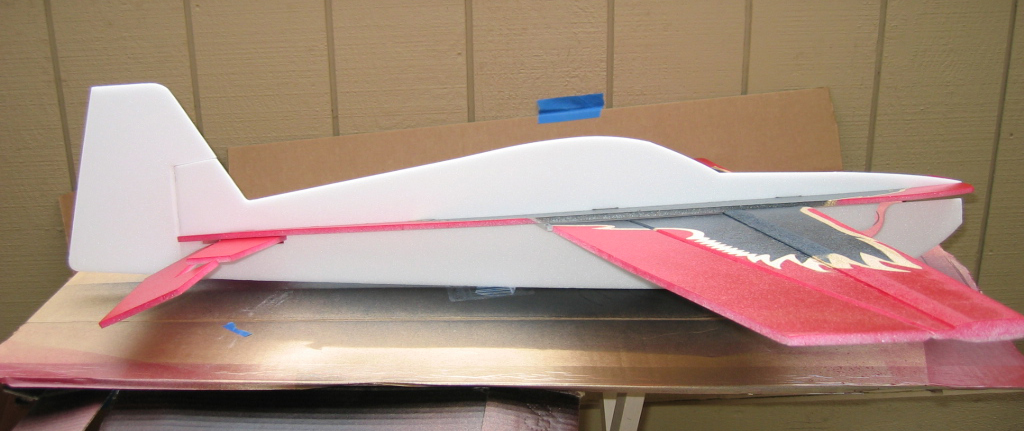

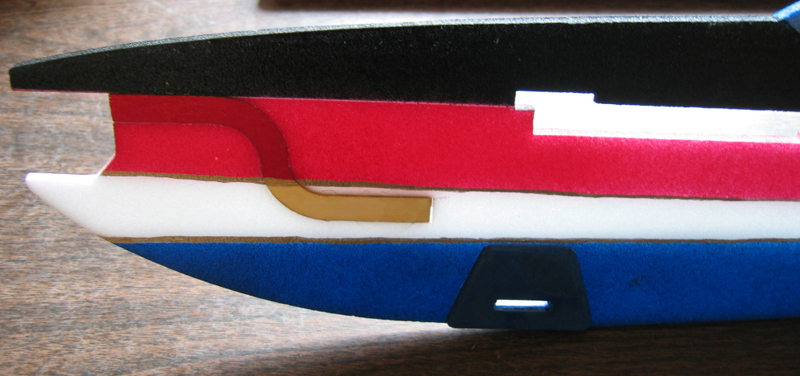

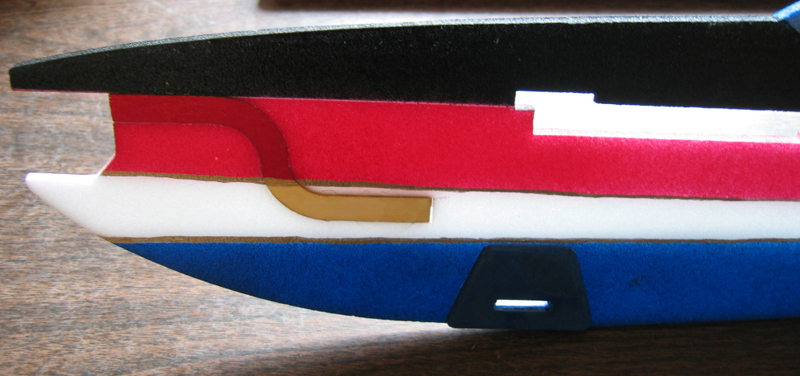

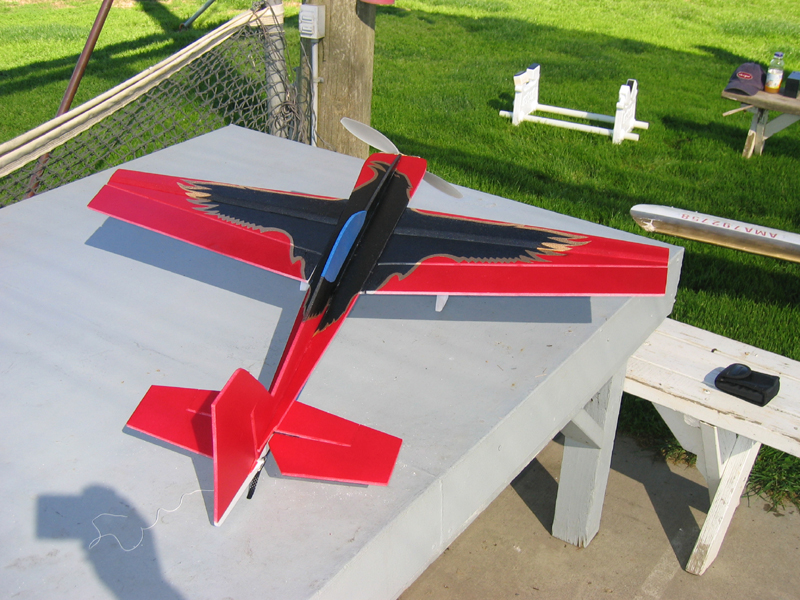

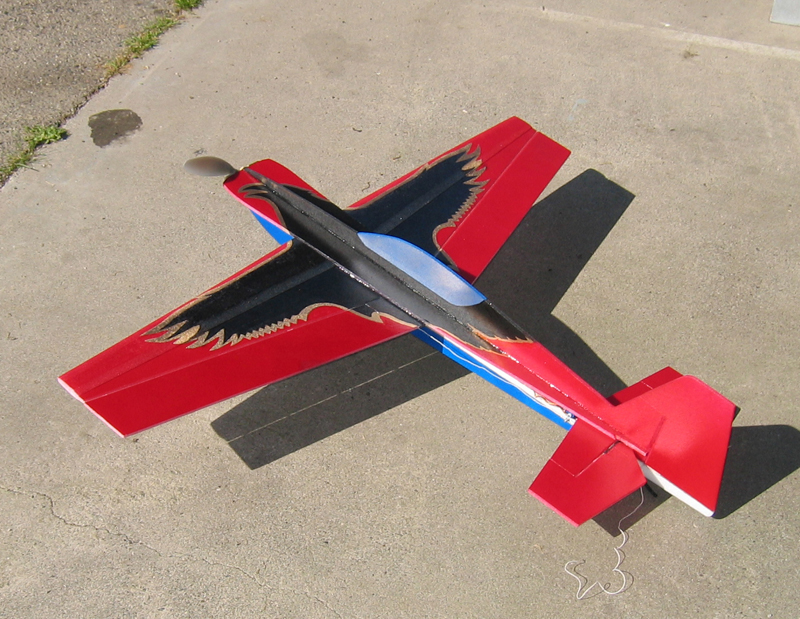

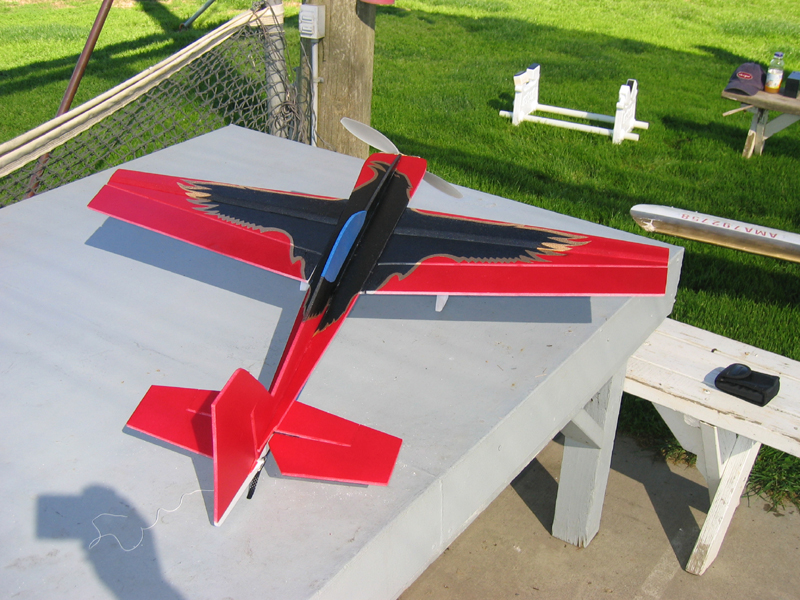

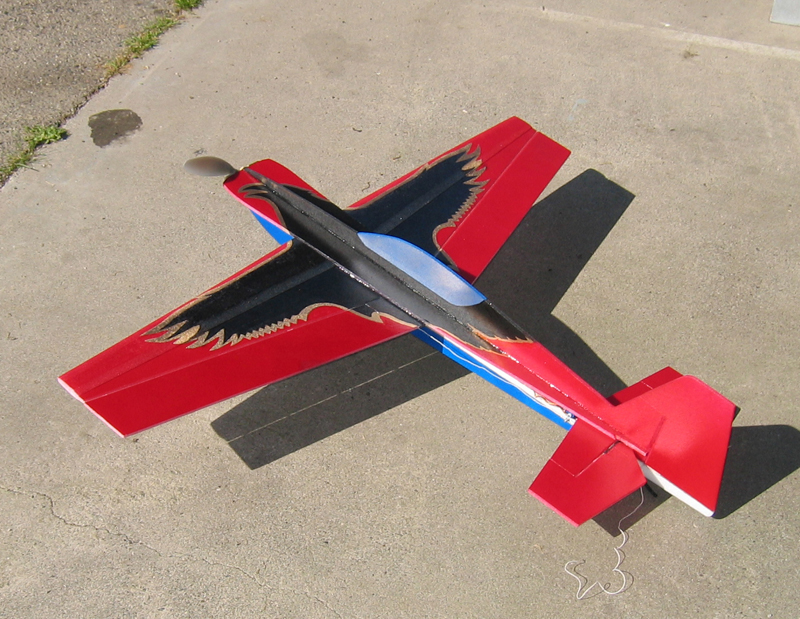

In preparation of making the side fuse stencil I did some side view shots and figured I would grab a top down view also for this post. Here is the complete airframe (though the parts aren't glued togther yet, and the elevators aren't hinged obviously) This shows how the top down paint will look with exception of the vertical portion of the fuse which will be painted once I get the motor mount.

Here is the complete airframe (though the parts aren't glued togther yet, and the elevators aren't hinged obviously) This shows how the top down paint will look with exception of the vertical portion of the fuse which will be painted once I get the motor mount.  Here is the side view.

Here is the side view. Another

Another

Here is the complete airframe (though the parts aren't glued togther yet, and the elevators aren't hinged obviously) This shows how the top down paint will look with exception of the vertical portion of the fuse which will be painted once I get the motor mount.

Here is the complete airframe (though the parts aren't glued togther yet, and the elevators aren't hinged obviously) This shows how the top down paint will look with exception of the vertical portion of the fuse which will be painted once I get the motor mount.  Here is the side view.

Here is the side view. Another

AnotherTitle: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-FlightRisk on February 12, 2005, 08:22:28 pm

Su Weet........S~TX-FlightRisk "If my plane is smoking it can mean one thing...I have been hit in one of my ass cheeks and I am cauterizing my wound....."

Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-Deck on February 13, 2005, 09:39:43 am

I dunno Eco, after looking at the size of that rudder, I think the plans may need to be revised to INCREASE the surface area....(that was sarcasm, in case it was lost in text)Can't wait for the video!TX-Deck out.

Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-EcoDragon on February 13, 2005, 07:58:16 pm

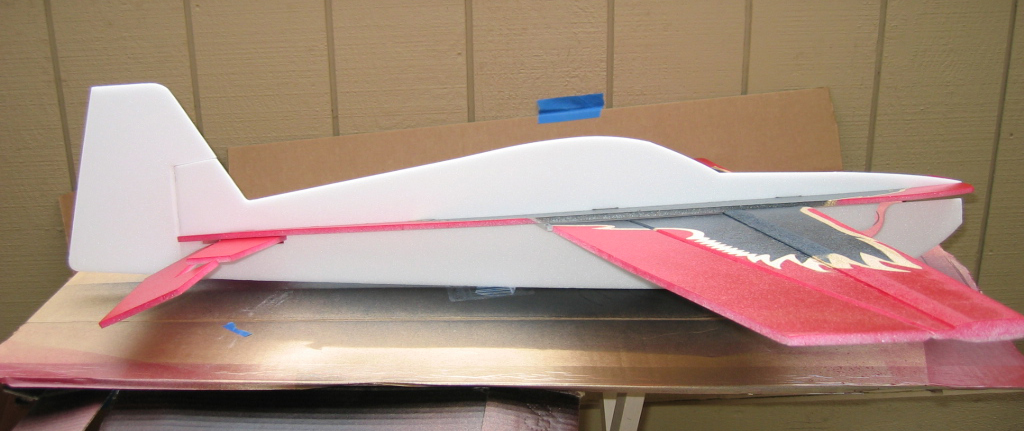

Here is the full scale 3 view. . . it's still got plenty of rudder, and other surfaces but not quite what the foamy has . that's for sure!!

Here is the full scale 3 view. . . it's still got plenty of rudder, and other surfaces but not quite what the foamy has . that's for sure!!Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-EcoDragon on February 13, 2005, 08:29:45 pm

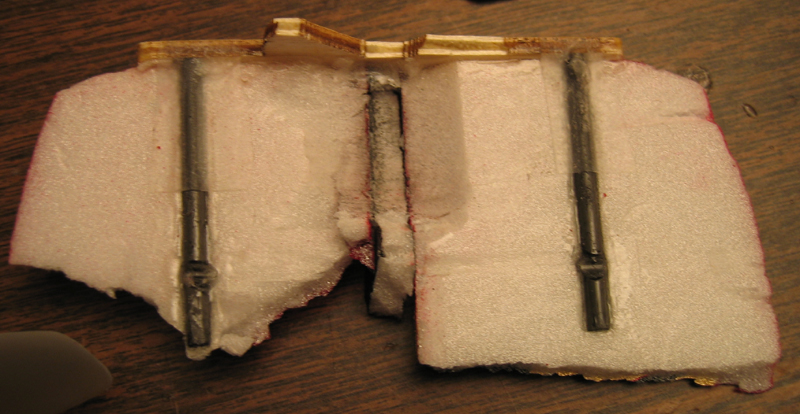

Here are the wheel pant components ready to build up on one of the pants. What you see here is the two solid side portions of the wheel pants, as well as the two spacers that you sandwhich between them to accomodate the wheel. There are two spacers provided, you can use one if the wheels are thin enough, in my case I used two to give some room for the wheels. The wheels are not included in the kit so you have a choice of which type you like to use. I opted for the MPI 2.0" as seen here.

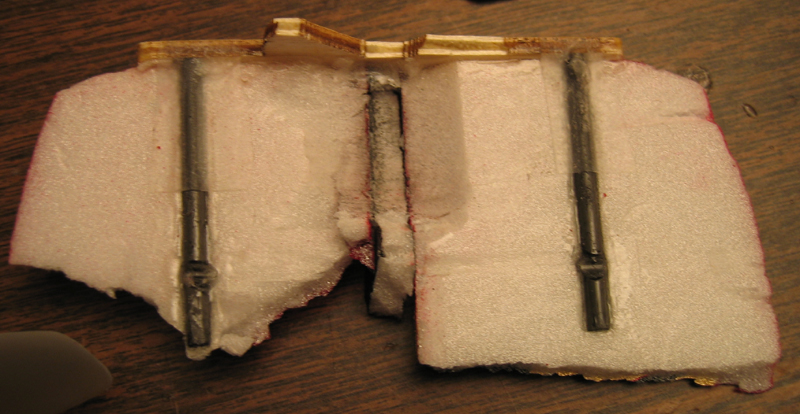

Here are the wheel pant components ready to build up on one of the pants. What you see here is the two solid side portions of the wheel pants, as well as the two spacers that you sandwhich between them to accomodate the wheel. There are two spacers provided, you can use one if the wheels are thin enough, in my case I used two to give some room for the wheels. The wheels are not included in the kit so you have a choice of which type you like to use. I opted for the MPI 2.0" as seen here. Here is how it looks assembled in cross section.

Here is how it looks assembled in cross section. Here is the whole pant assembled. I didn't end up using the accelerator, the glue seemed tacky enough and I didn't plan on sanding them round just yet. I just tossed some weight on them and let them cure. Next I will once again break out the contour sander and round these, then its time to paint them!

Here is the whole pant assembled. I didn't end up using the accelerator, the glue seemed tacky enough and I didn't plan on sanding them round just yet. I just tossed some weight on them and let them cure. Next I will once again break out the contour sander and round these, then its time to paint them! I am in the process of sanding the wheelpants to a more rounded and tapered shape. Here they are nearly completed.

I am in the process of sanding the wheelpants to a more rounded and tapered shape. Here they are nearly completed. Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-EcoDragon on February 14, 2005, 07:08:05 pm

Here is the mask for the white paint around the Raven's claws.

Here is the mask for the white paint around the Raven's claws. I had figured the wheel pants would be quick, but I opted to do the gold trim too, which is a very thin line of masking tape over lots of contours, and it ended up being a bit of a pain, and it still didn't look very good in the end. Not to mention that the dark blue I bought isnt all that dark when painted over white foam, but anyway, here is the first one I did. I figure it will look fine from 5 feet away anyhow . . . and im 6'2 so as long as I take off and land on the ground I should have nothing to worry about! ;-P

I had figured the wheel pants would be quick, but I opted to do the gold trim too, which is a very thin line of masking tape over lots of contours, and it ended up being a bit of a pain, and it still didn't look very good in the end. Not to mention that the dark blue I bought isnt all that dark when painted over white foam, but anyway, here is the first one I did. I figure it will look fine from 5 feet away anyhow . . . and im 6'2 so as long as I take off and land on the ground I should have nothing to worry about! ;-P Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-EcoDragon on February 17, 2005, 09:33:07 pm

I recieved another package today from 3D Foamy and it contained a complete Raven replacement kit, as well as a the non-pro Turbo Raven to boot! The AXI motor mounts were also included.

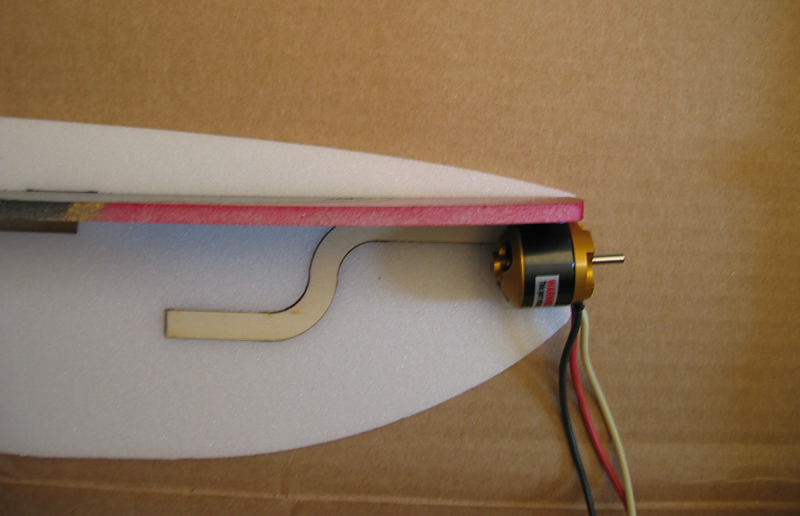

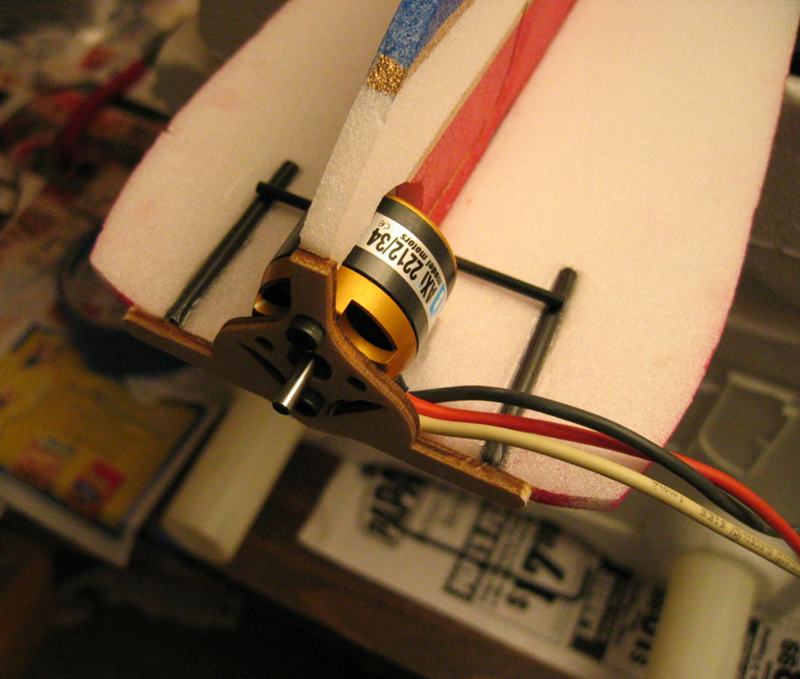

I recieved another package today from 3D Foamy and it contained a complete Raven replacement kit, as well as a the non-pro Turbo Raven to boot! The AXI motor mounts were also included. Here are the AXI motor mounts, there are two plywoods pieces in each package that must be epoxied together (EDIT: note that I didn't realize this when I built mine, and there were dire consequences as you will see later in this thread), the star shaped ones are for the turbo Raven/Giles kits, the cross shaped ones are for the Raven.

Here are the AXI motor mounts, there are two plywoods pieces in each package that must be epoxied together (EDIT: note that I didn't realize this when I built mine, and there were dire consequences as you will see later in this thread), the star shaped ones are for the turbo Raven/Giles kits, the cross shaped ones are for the Raven. Here is the mount ready to be installed or painted next to the motor.

Here is the mount ready to be installed or painted next to the motor. Trial fit of the "torqued" motor mount assembly.

Trial fit of the "torqued" motor mount assembly.  Now I am outlining the motor in preparation for cutting out the foam and triming the torqued mount.

Now I am outlining the motor in preparation for cutting out the foam and triming the torqued mount. Here is how it looks for my AXI installation.

Here is how it looks for my AXI installation.Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-EcoDragon on February 18, 2005, 02:52:44 am

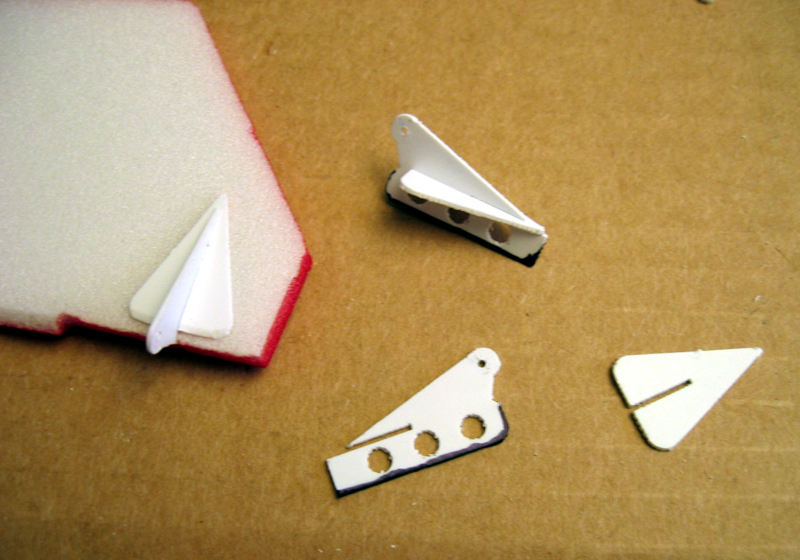

Here are the included control horns in various stages of assembly and installation, I just used a Sharpie marker to help blend the control horns in with their respective surfaces.

Here are the included control horns in various stages of assembly and installation, I just used a Sharpie marker to help blend the control horns in with their respective surfaces.  Here is the canopy area masked off for painting, I haven't really figured out what would look best, I didn't simply want the canopy to be black along with the Raven graphic, i was toying with silver or the blue that I already have.

Here is the canopy area masked off for painting, I haven't really figured out what would look best, I didn't simply want the canopy to be black along with the Raven graphic, i was toying with silver or the blue that I already have. Well, I decided I would try the blue for the canopy.

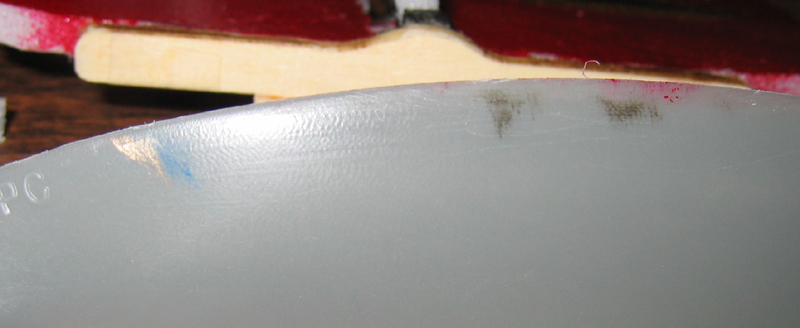

Well, I decided I would try the blue for the canopy. I don't really like the blue, but it would probably look good in the air. . . though I am thinking silver might have been a better way to emulate the canopy. . . a thin coat of silver over this might be just the ticket, but I will decide once it's all built up and flown. I have also started building my second Raven, it will be fully built without much paint as this is gonna be my basher. . . it should be done tomorrow along with this one.

I don't really like the blue, but it would probably look good in the air. . . though I am thinking silver might have been a better way to emulate the canopy. . . a thin coat of silver over this might be just the ticket, but I will decide once it's all built up and flown. I have also started building my second Raven, it will be fully built without much paint as this is gonna be my basher. . . it should be done tomorrow along with this one. Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-Rahman on February 18, 2005, 09:05:41 am

Eco...looks great!! For the canopy...maybe mask the canopy off again and kinda overspray the silver lightly over the blue so the blue still kinda shows through?  So you have three planes now?!?Regards,TX-Rahman"BLACK 4"

So you have three planes now?!?Regards,TX-Rahman"BLACK 4"

Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-EcoDragon on February 18, 2005, 03:27:45 pm

Yep, I have three of them! One will be a gift though! Of course I don't have any gear for another plane so it will be a backup for now.

Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-Deck on February 18, 2005, 04:07:24 pm

/me holds credit card in hand....SOOOO tempting, but I better keep on trucking with the Berkut first....Nice Work, I want VIDEO soon!TX-Deck out.

Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-EcoDragon on February 19, 2005, 12:54:00 am

Yeah Deck. . . you don't want to get sidtracked!!! Then again it's nice to have something to keep you having fun while you work away at that Berkut. Of course you've got the PT-40 for that I guess. . .that Berkut is not really an ideal second aircraft, it will probably be a bit of a challenge so getting lots of stick time on thw PT before you fly that is a wise idea!  Well, I picked up some silver spray enamel today, which I will add lightly over the blue canopy, which I will do tonight. Right now the fuse is outside with the lower blue stripe in progress, when those two things are done all the painting tasks are done, then I just need to install the components of the airframe, the radio and engien gear, which shouldn't take too long. . . maiden flight should be tomorrow!!Here is the fuse just before the lower blue strip was applied. I tried a Testors gold paint marker for the gold on the fuse, I did the tailfeather gold trim and the pinstripe betweent he red and white freehand, it looks almost as good as the mask and paint method, but takes a lot less time to do.

Well, I picked up some silver spray enamel today, which I will add lightly over the blue canopy, which I will do tonight. Right now the fuse is outside with the lower blue stripe in progress, when those two things are done all the painting tasks are done, then I just need to install the components of the airframe, the radio and engien gear, which shouldn't take too long. . . maiden flight should be tomorrow!!Here is the fuse just before the lower blue strip was applied. I tried a Testors gold paint marker for the gold on the fuse, I did the tailfeather gold trim and the pinstripe betweent he red and white freehand, it looks almost as good as the mask and paint method, but takes a lot less time to do.  Here is the Fuse witht he lower blue stripe and the second gold pinstripe completed.

Here is the Fuse witht he lower blue stripe and the second gold pinstripe completed.  Here are the parts for the carbon fiber gear assembly and mounting hardware. I sanded bevels onto the edges and painted the plywood portions blue to math the fuse where they mount.

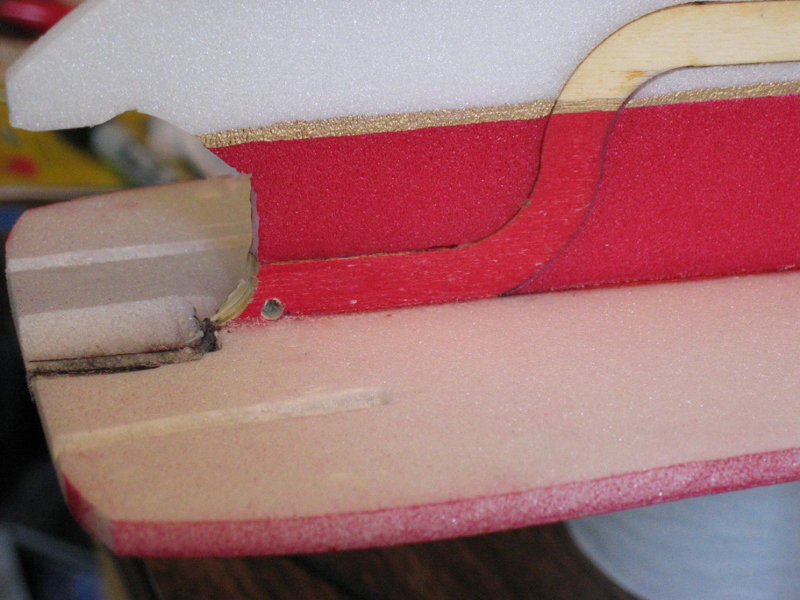

Here are the parts for the carbon fiber gear assembly and mounting hardware. I sanded bevels onto the edges and painted the plywood portions blue to math the fuse where they mount.  Here are the gear mounting plates installed and the hold is being cut for the gear to pass through. Post Maiden Edit: I would suggest adding some tape around the area of the ply mounts on the fuse, or perhaps a flat bar carbon rod on the bottom of the fuse in the area of the gear to distribute the loads over a greater area.

Here are the gear mounting plates installed and the hold is being cut for the gear to pass through. Post Maiden Edit: I would suggest adding some tape around the area of the ply mounts on the fuse, or perhaps a flat bar carbon rod on the bottom of the fuse in the area of the gear to distribute the loads over a greater area.

Well, I picked up some silver spray enamel today, which I will add lightly over the blue canopy, which I will do tonight. Right now the fuse is outside with the lower blue stripe in progress, when those two things are done all the painting tasks are done, then I just need to install the components of the airframe, the radio and engien gear, which shouldn't take too long. . . maiden flight should be tomorrow!!Here is the fuse just before the lower blue strip was applied. I tried a Testors gold paint marker for the gold on the fuse, I did the tailfeather gold trim and the pinstripe betweent he red and white freehand, it looks almost as good as the mask and paint method, but takes a lot less time to do.

Well, I picked up some silver spray enamel today, which I will add lightly over the blue canopy, which I will do tonight. Right now the fuse is outside with the lower blue stripe in progress, when those two things are done all the painting tasks are done, then I just need to install the components of the airframe, the radio and engien gear, which shouldn't take too long. . . maiden flight should be tomorrow!!Here is the fuse just before the lower blue strip was applied. I tried a Testors gold paint marker for the gold on the fuse, I did the tailfeather gold trim and the pinstripe betweent he red and white freehand, it looks almost as good as the mask and paint method, but takes a lot less time to do.  Here is the Fuse witht he lower blue stripe and the second gold pinstripe completed.

Here is the Fuse witht he lower blue stripe and the second gold pinstripe completed.  Here are the parts for the carbon fiber gear assembly and mounting hardware. I sanded bevels onto the edges and painted the plywood portions blue to math the fuse where they mount.

Here are the parts for the carbon fiber gear assembly and mounting hardware. I sanded bevels onto the edges and painted the plywood portions blue to math the fuse where they mount.  Here are the gear mounting plates installed and the hold is being cut for the gear to pass through. Post Maiden Edit: I would suggest adding some tape around the area of the ply mounts on the fuse, or perhaps a flat bar carbon rod on the bottom of the fuse in the area of the gear to distribute the loads over a greater area.

Here are the gear mounting plates installed and the hold is being cut for the gear to pass through. Post Maiden Edit: I would suggest adding some tape around the area of the ply mounts on the fuse, or perhaps a flat bar carbon rod on the bottom of the fuse in the area of the gear to distribute the loads over a greater area.Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-EcoDragon on February 19, 2005, 07:48:20 pm

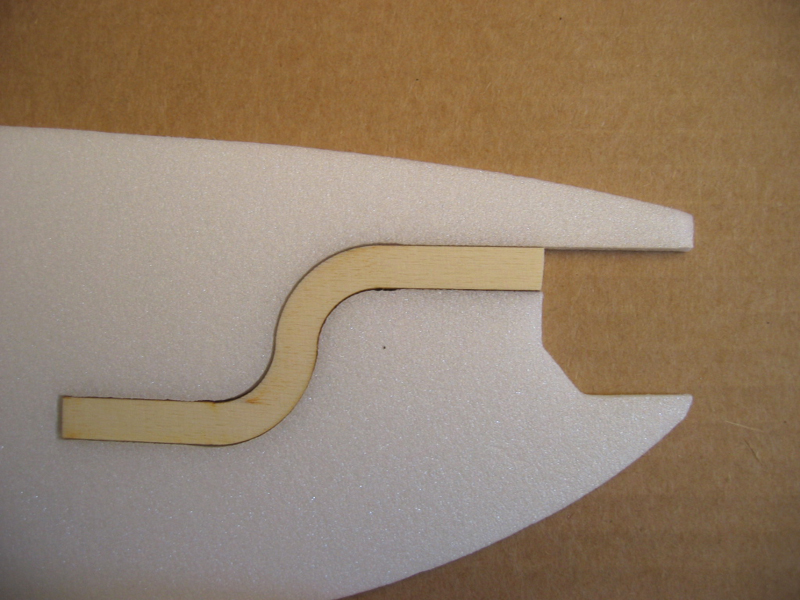

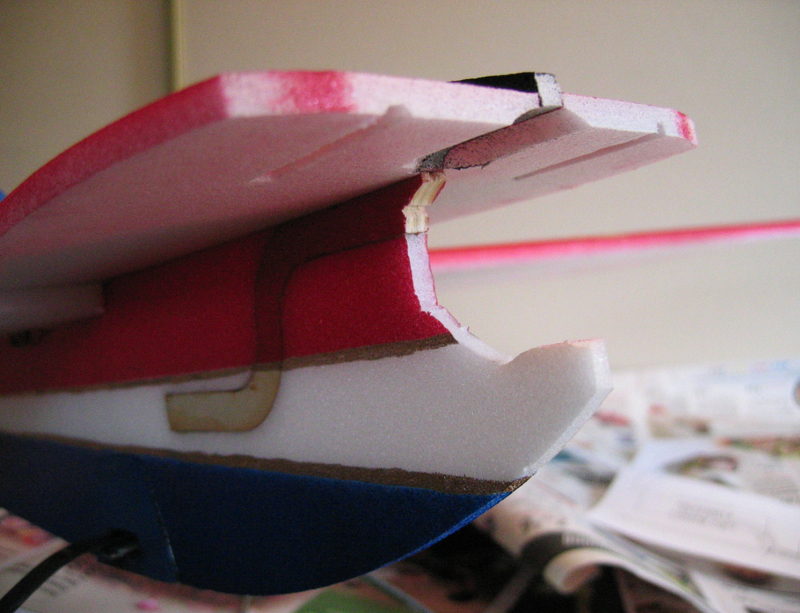

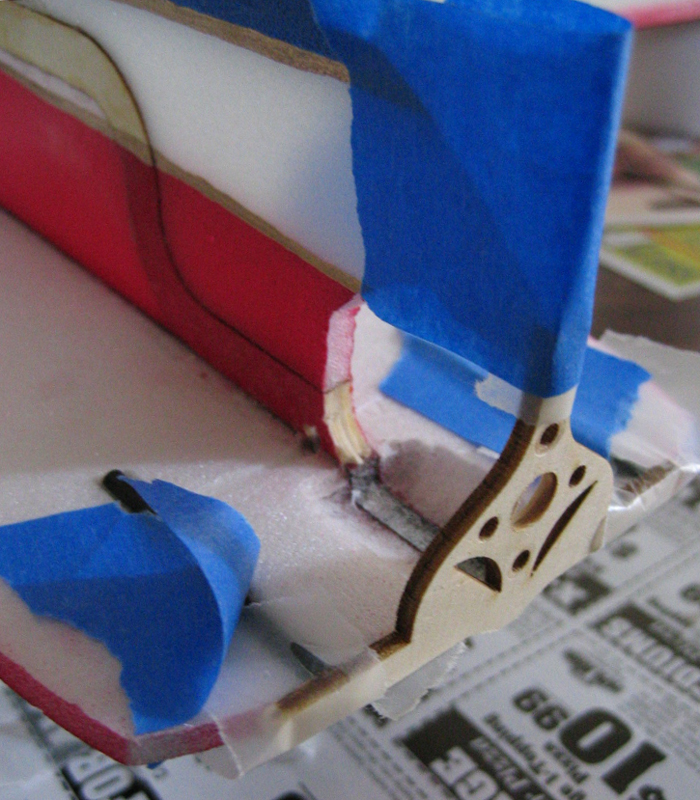

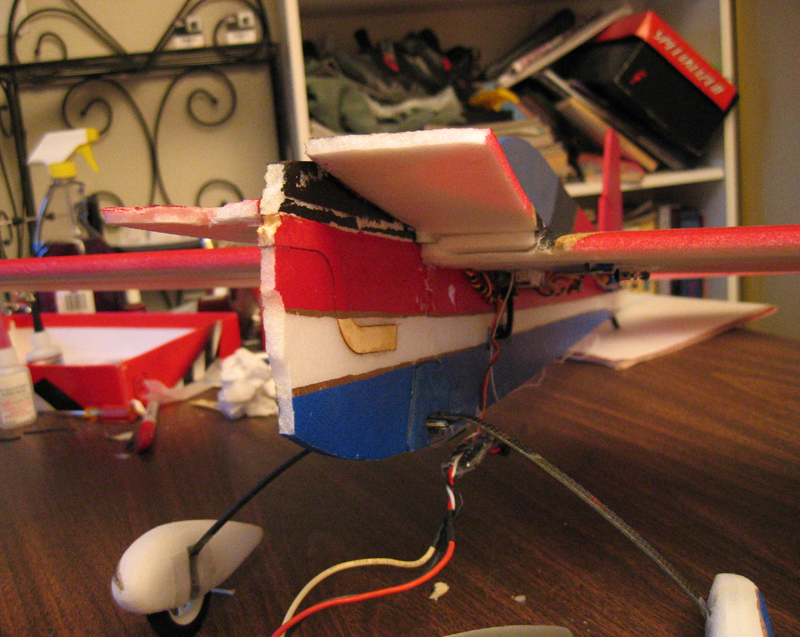

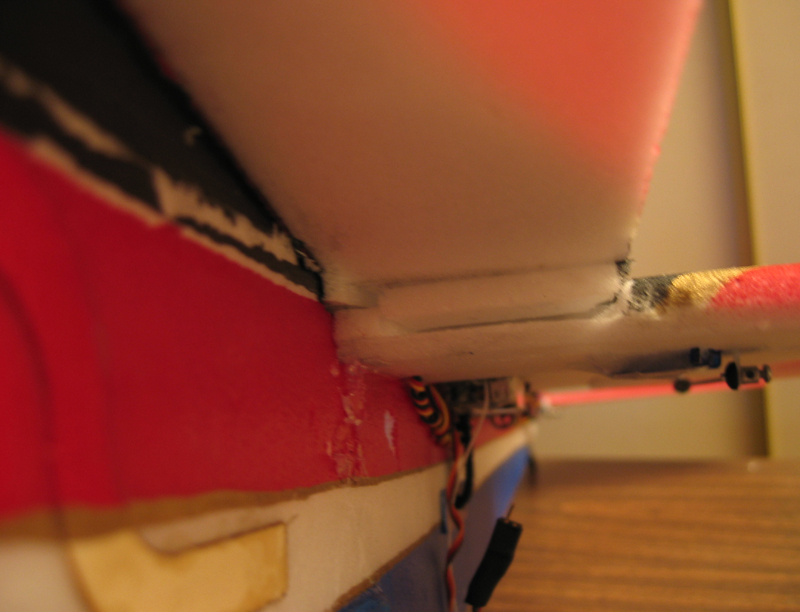

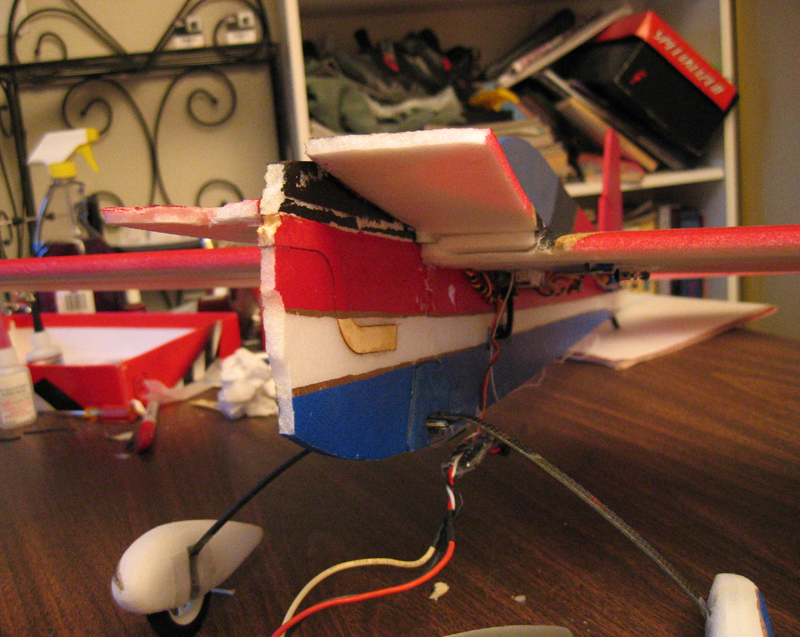

There has been some instances of failure of the front mounted firewall system so I decided to try adding a groove to the underside of each siderail that I will lay a carbon fiber tube in. This will mount up to the firewall mount and the fuse with some epoxy, I hand cut this, it's not pretty, but it should get the job done.

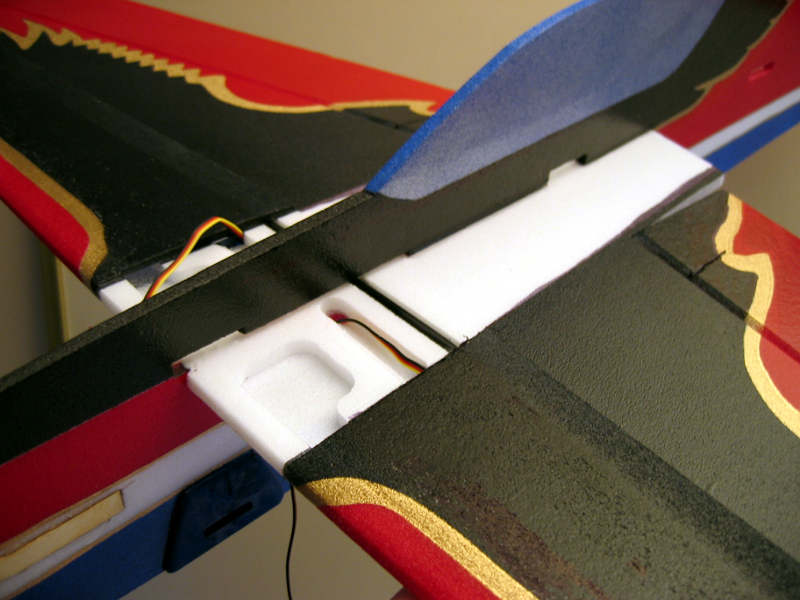

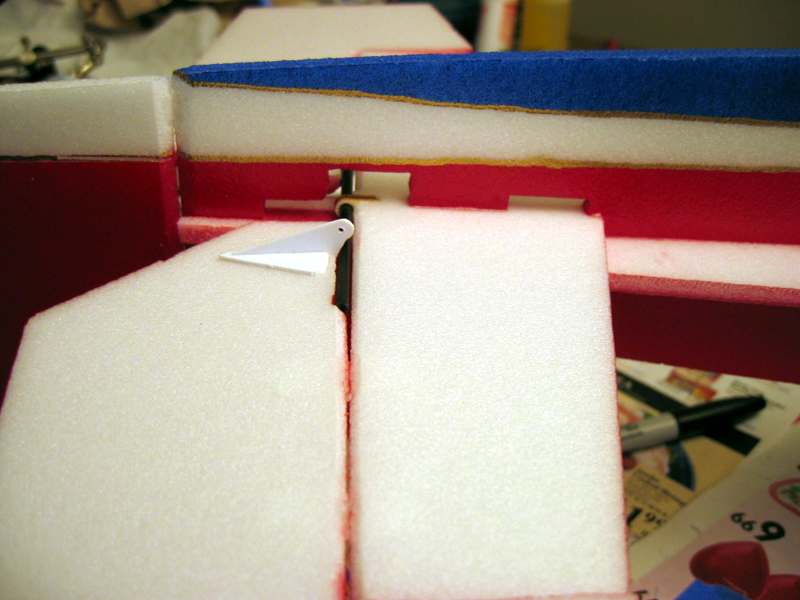

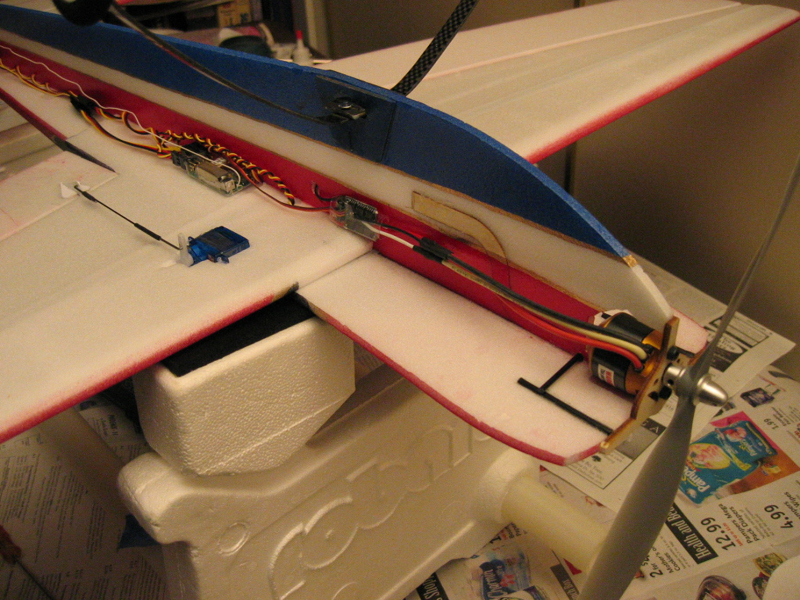

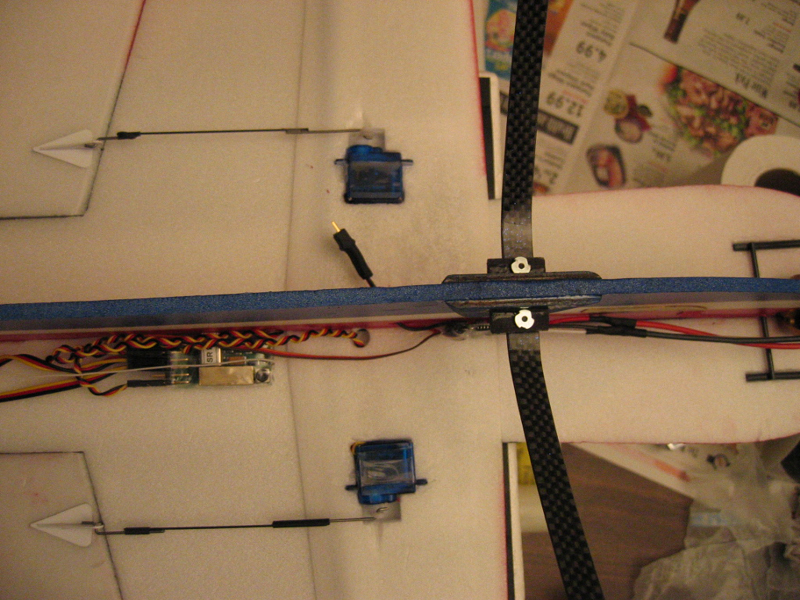

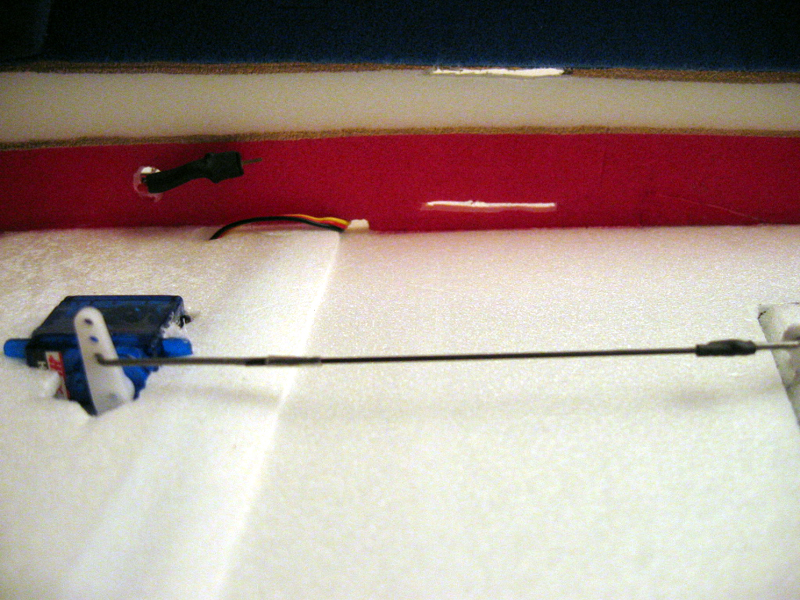

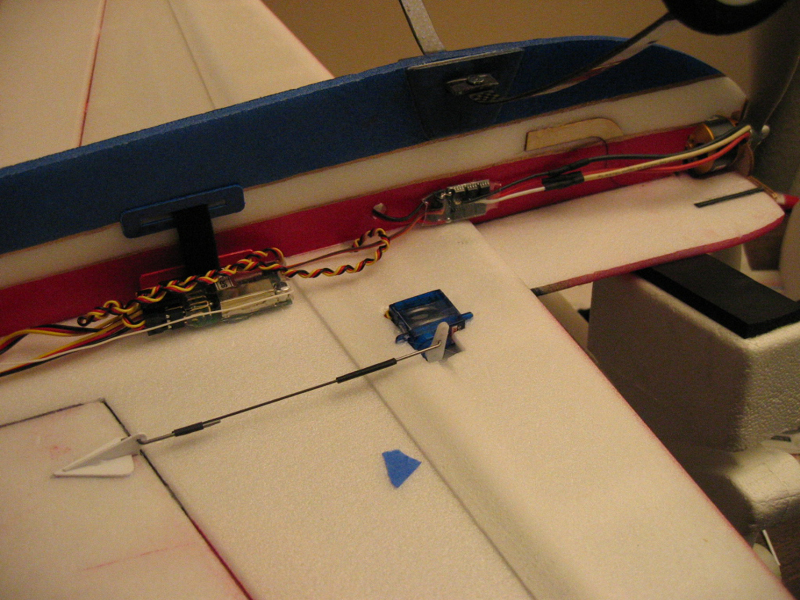

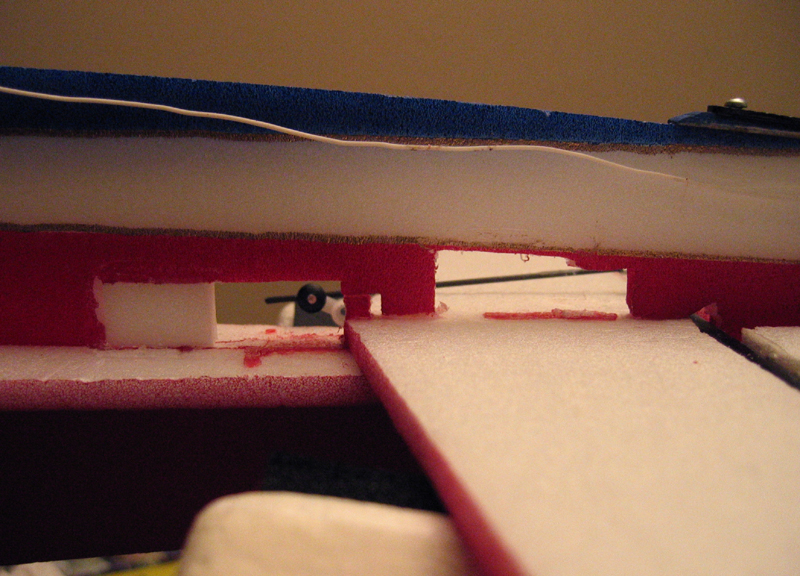

There has been some instances of failure of the front mounted firewall system so I decided to try adding a groove to the underside of each siderail that I will lay a carbon fiber tube in. This will mount up to the firewall mount and the fuse with some epoxy, I hand cut this, it's not pretty, but it should get the job done. Next I installed the tail feathers and wing, this is easier and helps protect the paint if you fold some wax paper aroudn the wing as you feed it through the slit in the fuse. I used a straight edge and square to check alignment and glued using CA and kicker, with some small areas of canopy glue. Before moving on it is probably a good idea to install the aileron servos in the wing, as there is a handly internal tube for the wires but it will be covered by the side rails so be sure to do this before installing the side rails! You can see the servo wires that will be hidden away here.

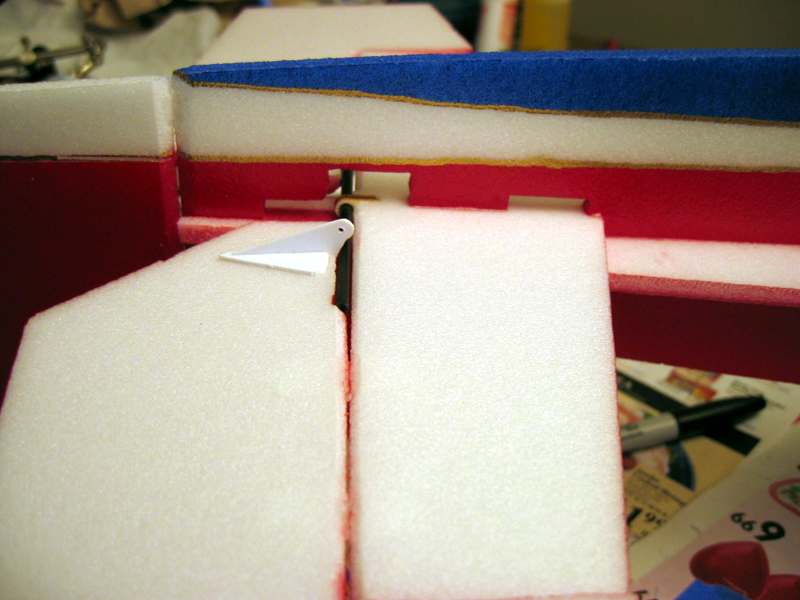

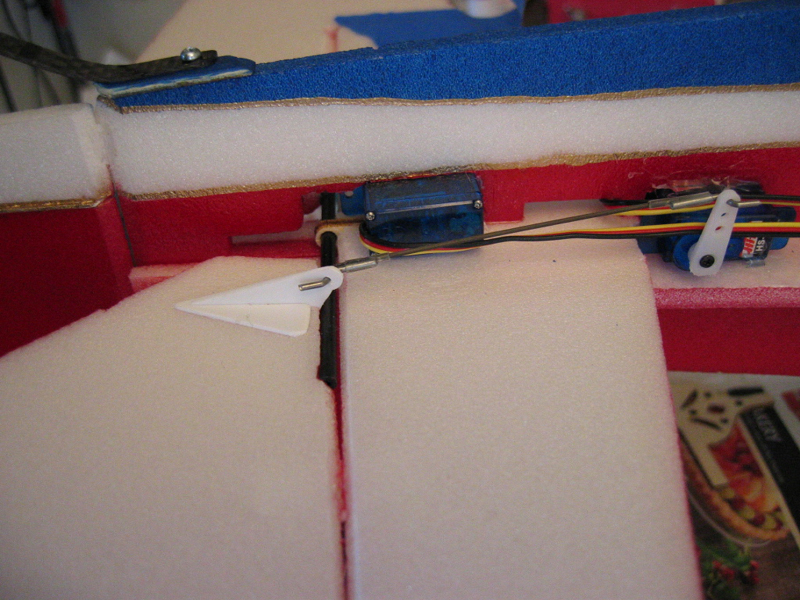

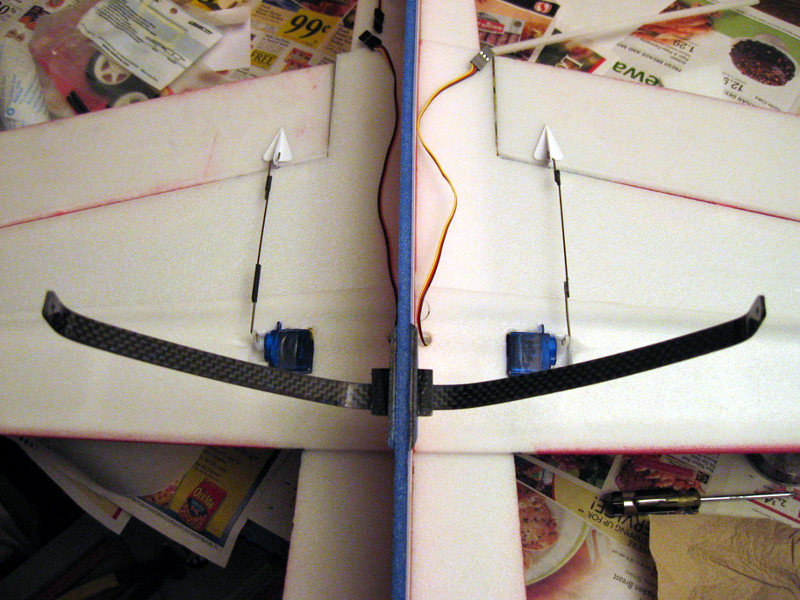

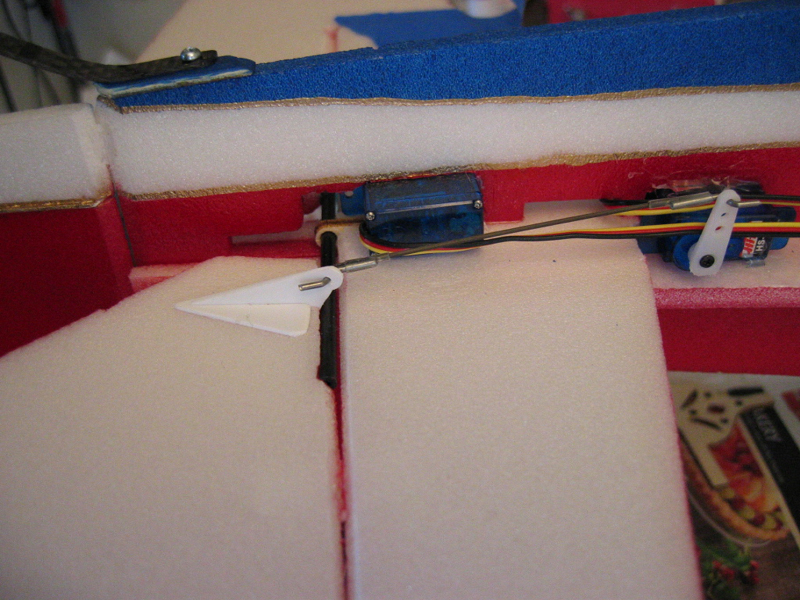

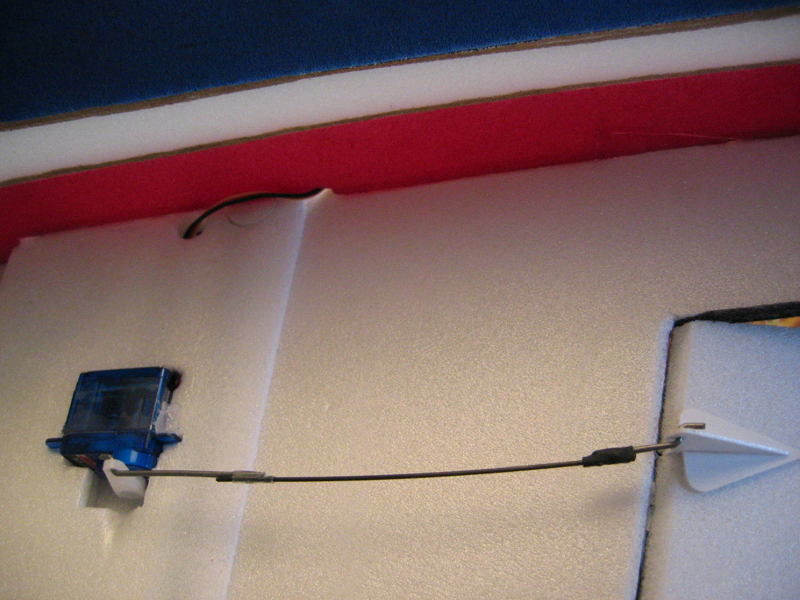

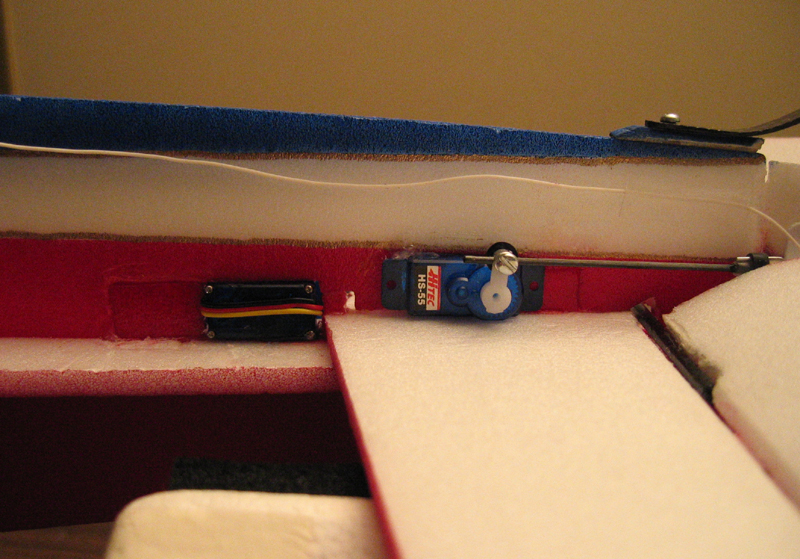

Next I installed the tail feathers and wing, this is easier and helps protect the paint if you fold some wax paper aroudn the wing as you feed it through the slit in the fuse. I used a straight edge and square to check alignment and glued using CA and kicker, with some small areas of canopy glue. Before moving on it is probably a good idea to install the aileron servos in the wing, as there is a handly internal tube for the wires but it will be covered by the side rails so be sure to do this before installing the side rails! You can see the servo wires that will be hidden away here. Here is the aileron servo installed in the nice little craddle. Something I'd like to see improved on is the aileron linkage geometry. . . the pushrods run perfectly lengthwise on the aircraft while the aileron hing line is swept forward. The aileron servo cradles should be canted a few degrees and the precut slots for the control horns should be angled in so that they are 90 degrees to the hinge line. I have a few suggestions that I will compile after a few more flights to send to Levi at 3D Foamy.Next I installed the side rails, and once done with those the basic airframe is complete, the landing gear will need to be isntalled, then it's jsut engine and radio gear installation to complete it. BTW, the weather is nice and stormy today, so I am in no big rush. :-/Here are a few pics of the current state of assmbly.

Here is the aileron servo installed in the nice little craddle. Something I'd like to see improved on is the aileron linkage geometry. . . the pushrods run perfectly lengthwise on the aircraft while the aileron hing line is swept forward. The aileron servo cradles should be canted a few degrees and the precut slots for the control horns should be angled in so that they are 90 degrees to the hinge line. I have a few suggestions that I will compile after a few more flights to send to Levi at 3D Foamy.Next I installed the side rails, and once done with those the basic airframe is complete, the landing gear will need to be isntalled, then it's jsut engine and radio gear installation to complete it. BTW, the weather is nice and stormy today, so I am in no big rush. :-/Here are a few pics of the current state of assmbly.

Stina's Chihuahua Ladybug insisted on being included in the pics. . .

Stina's Chihuahua Ladybug insisted on being included in the pics. . .

Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-CUDA on February 19, 2005, 09:14:00 pm

....Eco, What's your dog looking at out the back door?....LOL.,...Good Dog, Good Dog...TX-CudaMinister of Information

Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-FlightRisk on February 19, 2005, 09:40:32 pm

The plane is cool And you did an incredible job on it. LadyBug Rocks. Nice tri color Black and Tan!! You gotta like those lil dogs... I have two of them....S~TX-FlightRisk "If my plane is smoking it can mean one thing...I have been hit in one of my ass cheeks and I am cauterizing my wound....."

Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-Deck on February 19, 2005, 11:17:34 pm

The dog never moves... we need more pics to make sure it isn't "stuffed".Ok, that's a rather strange thought......nevermind.Great work on the Raven, still can't wait for Video!TX-Deck out.

Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-EcoDragon on February 20, 2005, 05:49:21 pm

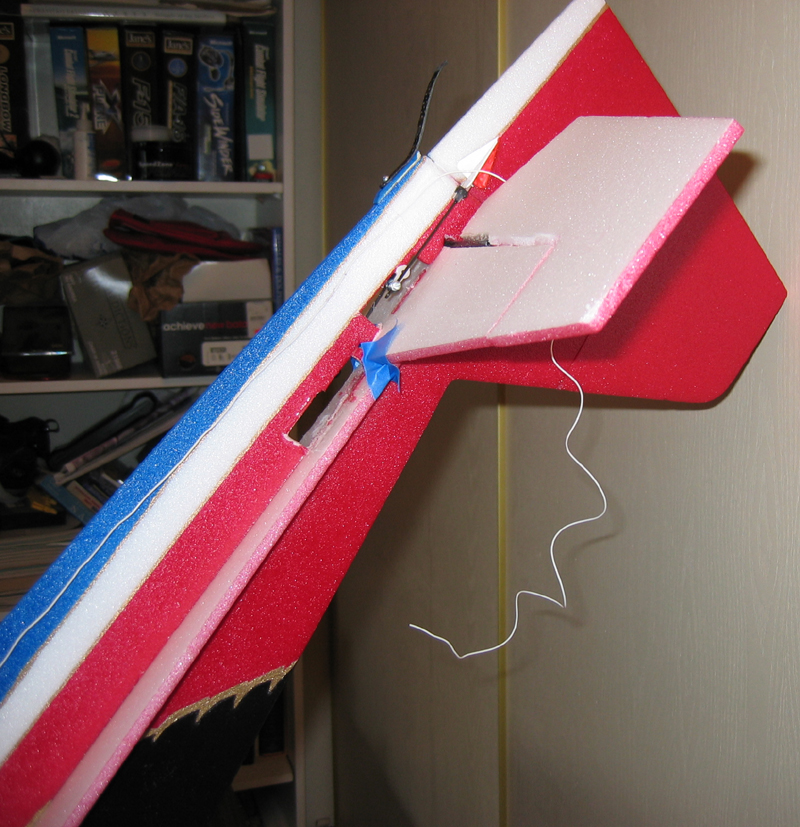

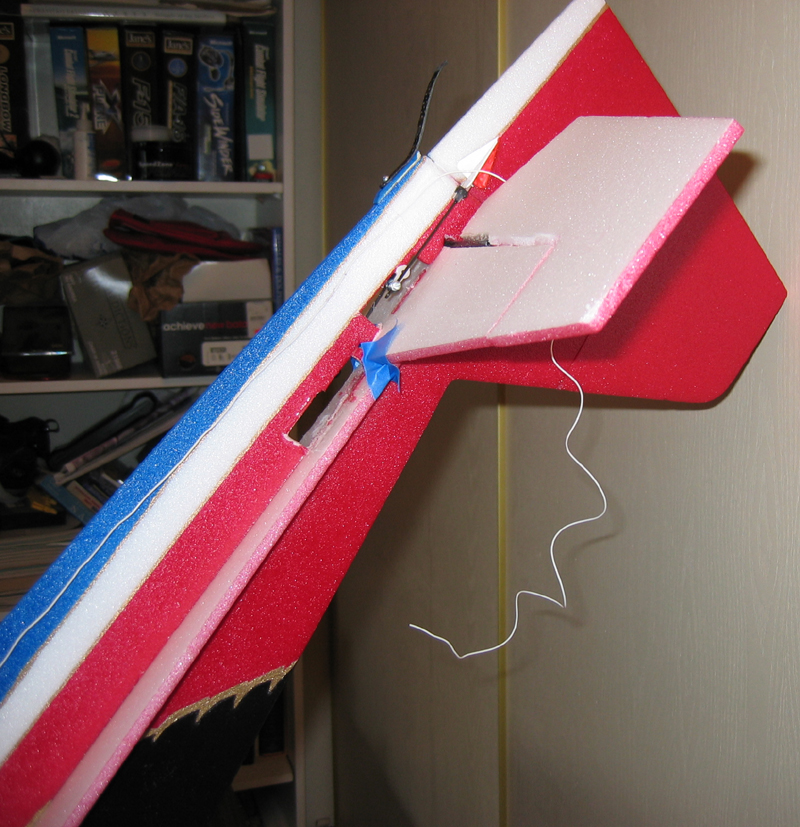

There is a problem in the manual that has caused me some grief. The thing that makes it a little confusing is the wording in step 14 that states: "Slide the stab through the cutout. When centered push the stab forward into the centering notch." Well, it seems that that is wrong, the pictures depict the surface slid all the way back in the cutout, not forward. In the online manual pics it's clear from looking at them, but in my own printed copy it wasn't so I used the text more than the pics. I followed the text, and I didn't notice the issue until shortly after the glue had cured so I was faced with the option to try to cut the tail free and move it or fly it with the horizontal stabilizer and elevator halves 2/3 of an inch farther forward than they should be. . . the Raven already has a long tail moment, it should be fine, but wont be as easy to hover or rolling harriers.  Here you can see the mistake I made, the space behind the black CF rod shouldn't be there.

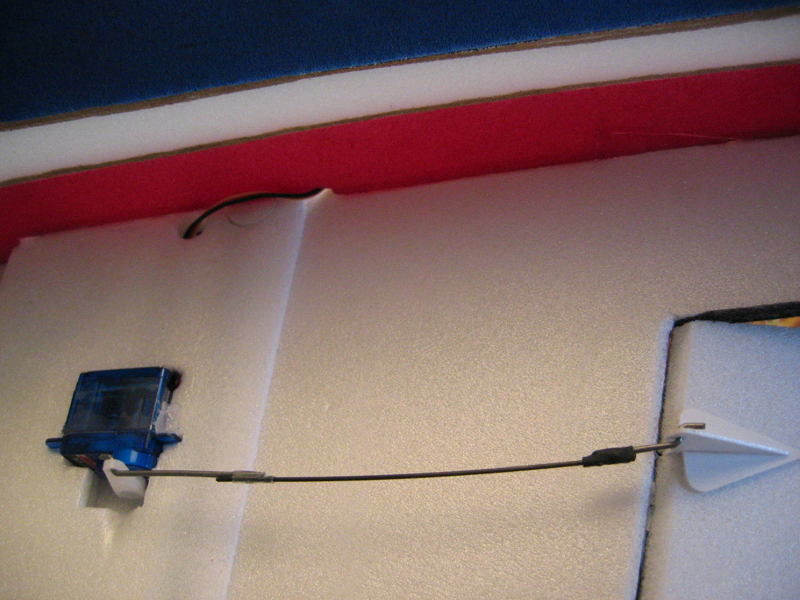

Here you can see the mistake I made, the space behind the black CF rod shouldn't be there. I had to cut the slots for the servos since the pre-cut ones couldn't be used after the goof up on the tail. Here is the completed installation including the carbon fiber tailskid, and the pushrods.

I had to cut the slots for the servos since the pre-cut ones couldn't be used after the goof up on the tail. Here is the completed installation including the carbon fiber tailskid, and the pushrods.  Here is a better shot of the CF tailskid. EDIT: I suggest adding heat shrink tubing to the tailskid at the tip of it to keep it from getting sanded down when taking off and landing on hard surfaces.This seems like the lightest, best looking, and most durable method. The carbon fiber itself WILL grind down very quickly otherwise. If you take off of concrete, do this!

Here is a better shot of the CF tailskid. EDIT: I suggest adding heat shrink tubing to the tailskid at the tip of it to keep it from getting sanded down when taking off and landing on hard surfaces.This seems like the lightest, best looking, and most durable method. The carbon fiber itself WILL grind down very quickly otherwise. If you take off of concrete, do this!  The supplied pushrod set up is too flexy for me to feel comfortable using them, I made all of them and installed them, but they are about half as strong as those that come on the shockflyer. . and those were too flexy too!I will probably replace these with the dubro micro pushrod system. This may be solved by using the full length of the Z-bent wire and cutting down the CF a bit more instead of vice versa.

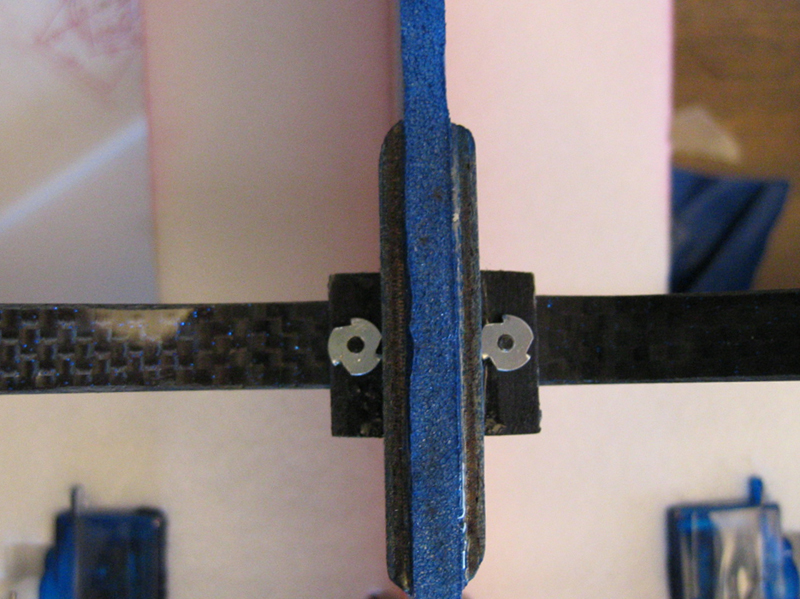

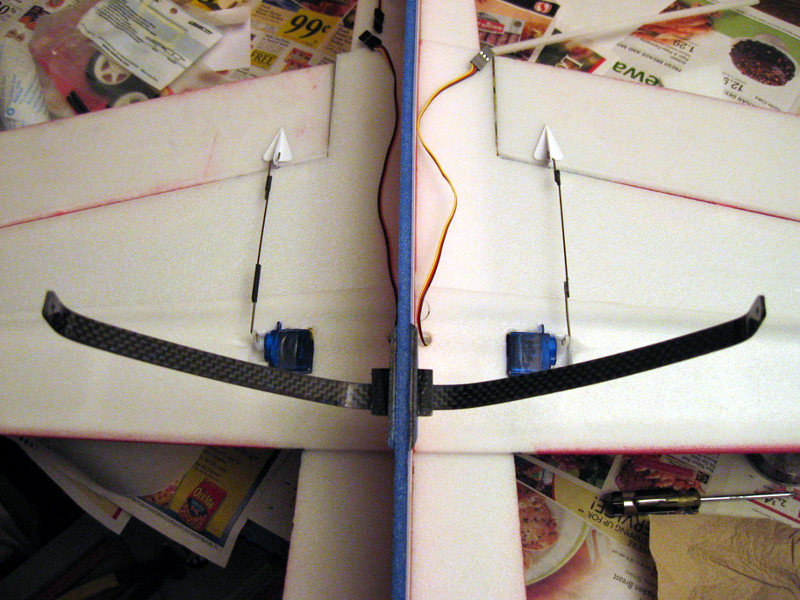

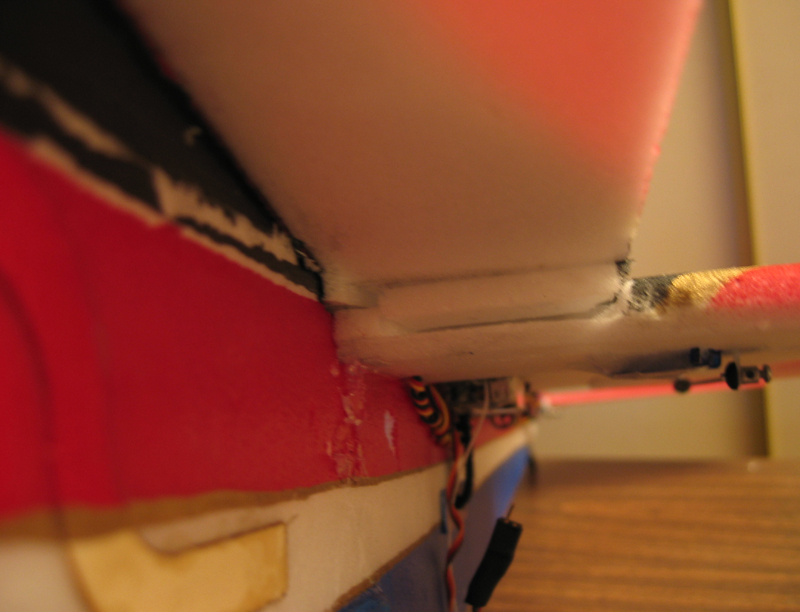

The supplied pushrod set up is too flexy for me to feel comfortable using them, I made all of them and installed them, but they are about half as strong as those that come on the shockflyer. . and those were too flexy too!I will probably replace these with the dubro micro pushrod system. This may be solved by using the full length of the Z-bent wire and cutting down the CF a bit more instead of vice versa. Here the gear are being assembled, In the above pic I am preparing to install the blind nuts and screws through the CF and balsa ply. the mounts are epoxied in place, I suggest doing the side plates first (just be sure they are lined up so the gear sit level), and once they are cured install the pass through plate of ply *and* CF gear legs and then add some epoxy to the pass through ply. In my installation the gear fit very tightly inside, there would have been no way to fit them through after fitting the ply side plates and pass through, at least without risking damage to the CF legs.

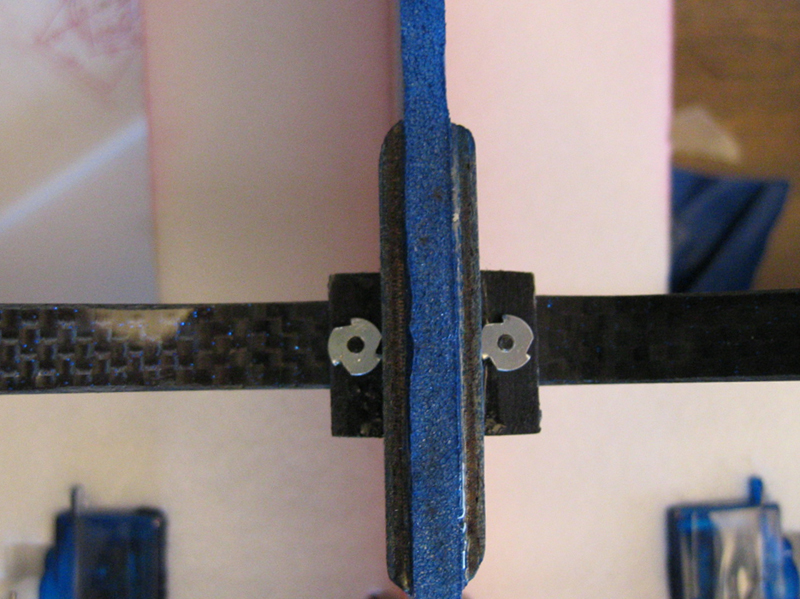

Here the gear are being assembled, In the above pic I am preparing to install the blind nuts and screws through the CF and balsa ply. the mounts are epoxied in place, I suggest doing the side plates first (just be sure they are lined up so the gear sit level), and once they are cured install the pass through plate of ply *and* CF gear legs and then add some epoxy to the pass through ply. In my installation the gear fit very tightly inside, there would have been no way to fit them through after fitting the ply side plates and pass through, at least without risking damage to the CF legs.  Here is the bottom of the gear mounting assembly once completed.

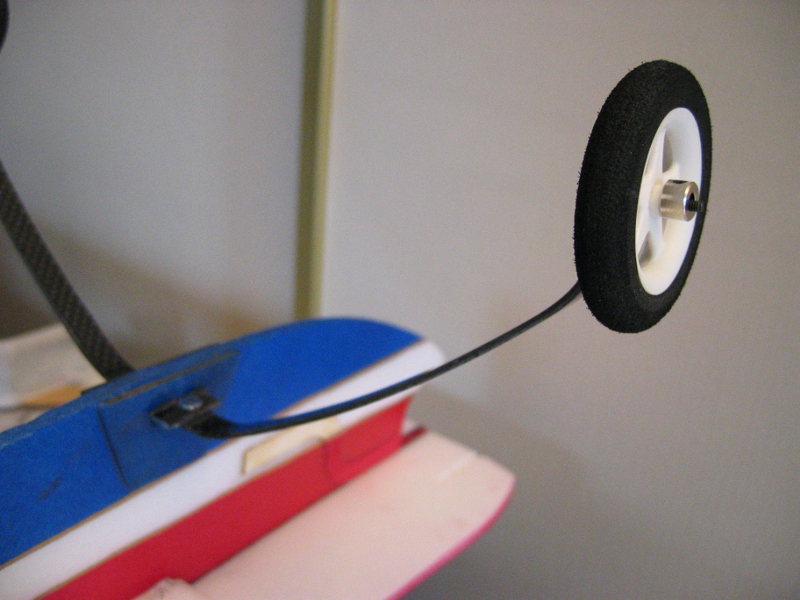

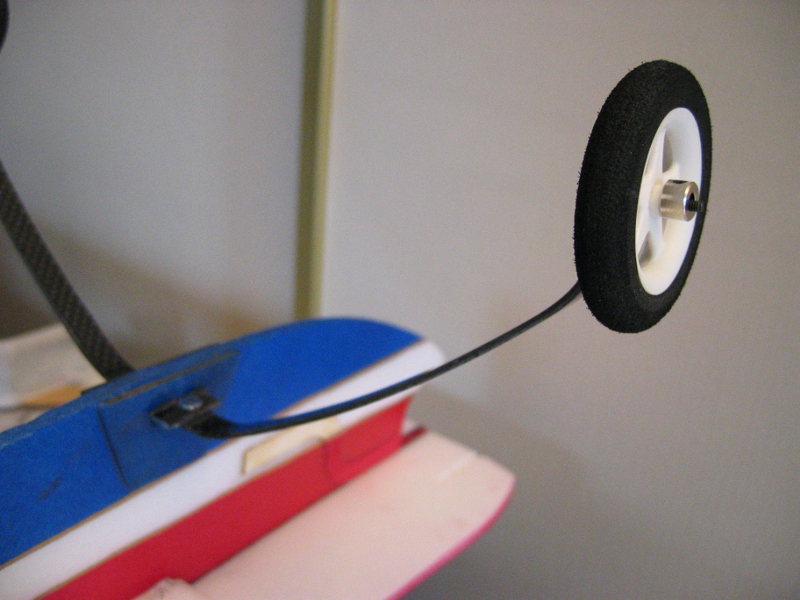

Here is the bottom of the gear mounting assembly once completed. Thread the 2-56 screw and washer through the CF, isntall the nut, then the wheel, and lastly a 1/8 wheel collar to complete the gear and wheel installation.

Thread the 2-56 screw and washer through the CF, isntall the nut, then the wheel, and lastly a 1/8 wheel collar to complete the gear and wheel installation.  Well, my nice tidy cutouts needed to be redone since the front mount setup required some repositioning of things aft. This is before I sanded it down a bit to make it look a little smoother.

Well, my nice tidy cutouts needed to be redone since the front mount setup required some repositioning of things aft. This is before I sanded it down a bit to make it look a little smoother. I also cut a pass through the "torqued" motor mount, through this I will place a small CF rod, my intention is to distribute the torque through the ply mount so it isn't all going into the fairly weak foam nose side rails. If using this mount system you should probably use a little tape over the mount and rails just as a precaution. . . and be sure to include this area on your pre-flight.

I also cut a pass through the "torqued" motor mount, through this I will place a small CF rod, my intention is to distribute the torque through the ply mount so it isn't all going into the fairly weak foam nose side rails. If using this mount system you should probably use a little tape over the mount and rails just as a precaution. . . and be sure to include this area on your pre-flight.  Here are the CF rods I installed to beef up the nose assembly. I used some 5 minute epoxy here.

Here are the CF rods I installed to beef up the nose assembly. I used some 5 minute epoxy here. Here you see the installation of the firewall using 30 minute epoxy.

Here you see the installation of the firewall using 30 minute epoxy.

Here you can see the mistake I made, the space behind the black CF rod shouldn't be there.

Here you can see the mistake I made, the space behind the black CF rod shouldn't be there. I had to cut the slots for the servos since the pre-cut ones couldn't be used after the goof up on the tail. Here is the completed installation including the carbon fiber tailskid, and the pushrods.

I had to cut the slots for the servos since the pre-cut ones couldn't be used after the goof up on the tail. Here is the completed installation including the carbon fiber tailskid, and the pushrods.  Here is a better shot of the CF tailskid. EDIT: I suggest adding heat shrink tubing to the tailskid at the tip of it to keep it from getting sanded down when taking off and landing on hard surfaces.This seems like the lightest, best looking, and most durable method. The carbon fiber itself WILL grind down very quickly otherwise. If you take off of concrete, do this!

Here is a better shot of the CF tailskid. EDIT: I suggest adding heat shrink tubing to the tailskid at the tip of it to keep it from getting sanded down when taking off and landing on hard surfaces.This seems like the lightest, best looking, and most durable method. The carbon fiber itself WILL grind down very quickly otherwise. If you take off of concrete, do this!  The supplied pushrod set up is too flexy for me to feel comfortable using them, I made all of them and installed them, but they are about half as strong as those that come on the shockflyer. . and those were too flexy too!I will probably replace these with the dubro micro pushrod system. This may be solved by using the full length of the Z-bent wire and cutting down the CF a bit more instead of vice versa.

The supplied pushrod set up is too flexy for me to feel comfortable using them, I made all of them and installed them, but they are about half as strong as those that come on the shockflyer. . and those were too flexy too!I will probably replace these with the dubro micro pushrod system. This may be solved by using the full length of the Z-bent wire and cutting down the CF a bit more instead of vice versa. Here the gear are being assembled, In the above pic I am preparing to install the blind nuts and screws through the CF and balsa ply. the mounts are epoxied in place, I suggest doing the side plates first (just be sure they are lined up so the gear sit level), and once they are cured install the pass through plate of ply *and* CF gear legs and then add some epoxy to the pass through ply. In my installation the gear fit very tightly inside, there would have been no way to fit them through after fitting the ply side plates and pass through, at least without risking damage to the CF legs.

Here the gear are being assembled, In the above pic I am preparing to install the blind nuts and screws through the CF and balsa ply. the mounts are epoxied in place, I suggest doing the side plates first (just be sure they are lined up so the gear sit level), and once they are cured install the pass through plate of ply *and* CF gear legs and then add some epoxy to the pass through ply. In my installation the gear fit very tightly inside, there would have been no way to fit them through after fitting the ply side plates and pass through, at least without risking damage to the CF legs.  Here is the bottom of the gear mounting assembly once completed.

Here is the bottom of the gear mounting assembly once completed. Thread the 2-56 screw and washer through the CF, isntall the nut, then the wheel, and lastly a 1/8 wheel collar to complete the gear and wheel installation.

Thread the 2-56 screw and washer through the CF, isntall the nut, then the wheel, and lastly a 1/8 wheel collar to complete the gear and wheel installation.  Well, my nice tidy cutouts needed to be redone since the front mount setup required some repositioning of things aft. This is before I sanded it down a bit to make it look a little smoother.

Well, my nice tidy cutouts needed to be redone since the front mount setup required some repositioning of things aft. This is before I sanded it down a bit to make it look a little smoother. I also cut a pass through the "torqued" motor mount, through this I will place a small CF rod, my intention is to distribute the torque through the ply mount so it isn't all going into the fairly weak foam nose side rails. If using this mount system you should probably use a little tape over the mount and rails just as a precaution. . . and be sure to include this area on your pre-flight.

I also cut a pass through the "torqued" motor mount, through this I will place a small CF rod, my intention is to distribute the torque through the ply mount so it isn't all going into the fairly weak foam nose side rails. If using this mount system you should probably use a little tape over the mount and rails just as a precaution. . . and be sure to include this area on your pre-flight.  Here are the CF rods I installed to beef up the nose assembly. I used some 5 minute epoxy here.

Here are the CF rods I installed to beef up the nose assembly. I used some 5 minute epoxy here. Here you see the installation of the firewall using 30 minute epoxy.

Here you see the installation of the firewall using 30 minute epoxy.Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-EcoDragon on February 21, 2005, 02:35:43 am

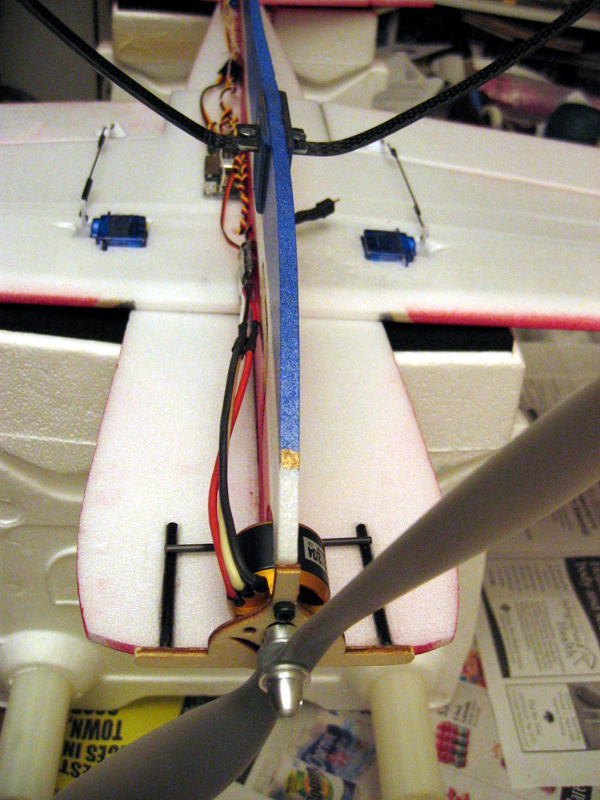

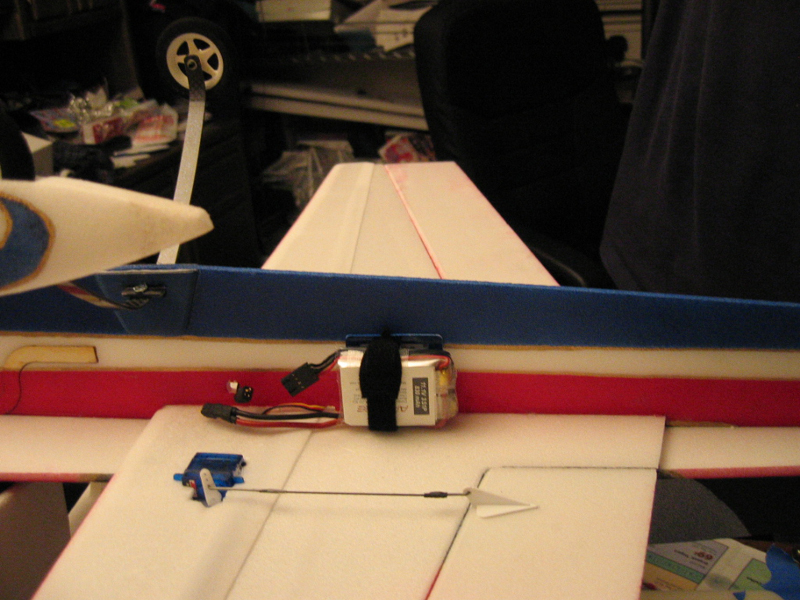

Here is the motor installed.

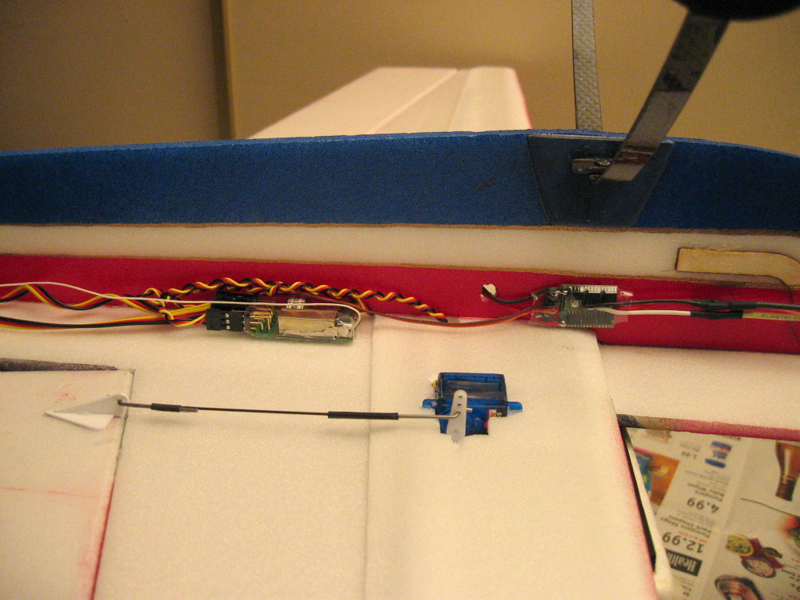

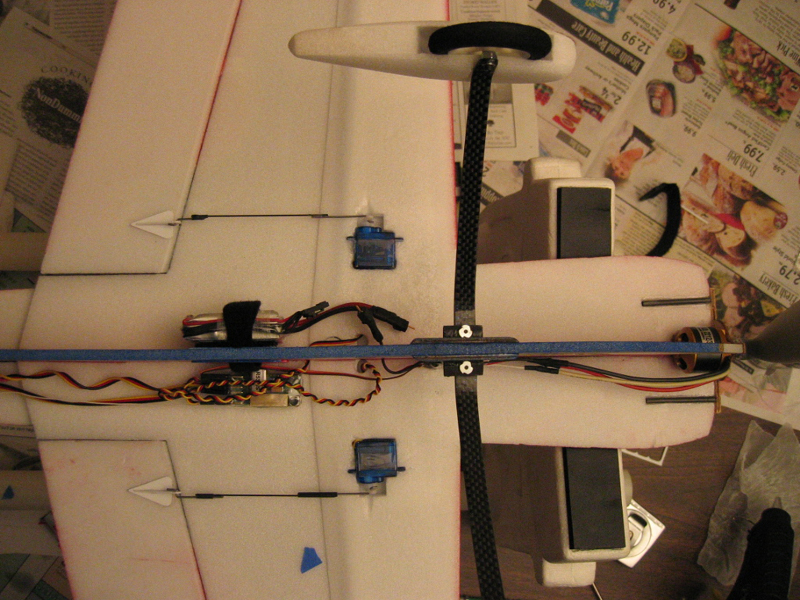

Here is the motor installed. Here are a couple shots of the radio gear and ESC installed.

Here are a couple shots of the radio gear and ESC installed. The receiver and ESC are mounted under the left wing as seen here, there is a small hole as a pass through for the battery connector as I was going to mount the battery on the right side.

The receiver and ESC are mounted under the left wing as seen here, there is a small hole as a pass through for the battery connector as I was going to mount the battery on the right side.

Title: Re: TX-EcoDragon's 3D Foamy Raven Build Thread

Post by: TX-EcoDragon on February 21, 2005, 05:31:00 pm

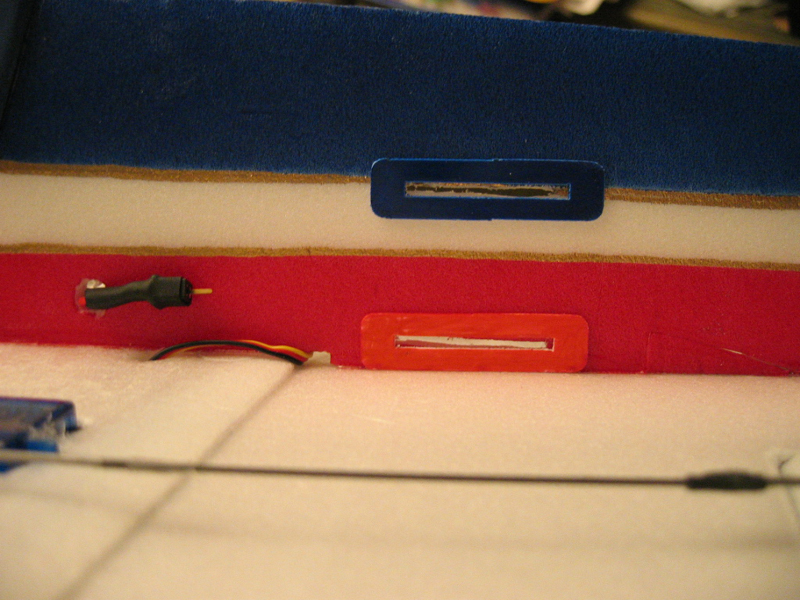

After checking CG I verified this is the location for my battery I made two slots in the fuse for the included velcro strap to pass through. These should be oriented this way to permit shifting the pack fore and aft to shift CG as needed.

After checking CG I verified this is the location for my battery I made two slots in the fuse for the included velcro strap to pass through. These should be oriented this way to permit shifting the pack fore and aft to shift CG as needed. Next I used a little CA and kicker to apply the plastic doublers to each side of the fuse at the slots. These will keep the strap from cutting into the foam.

Next I used a little CA and kicker to apply the plastic doublers to each side of the fuse at the slots. These will keep the strap from cutting into the foam.  This is the velcro strap installed, as well as some velcro that will prevent the pack from sliding forward or backwards in the strap.

This is the velcro strap installed, as well as some velcro that will prevent the pack from sliding forward or backwards in the strap.  Here is one of the batteries installed (corresponding velcro on the back).

Here is one of the batteries installed (corresponding velcro on the back). Here is the other side with the radio gear. Note that the blue tape indicates the desired CG range.

Here is the other side with the radio gear. Note that the blue tape indicates the desired CG range. And here is how it all looks in mine.

And here is how it all looks in mine. Now that your all done it's a good time to add the wheel pants, they require some cutting to get the best fit on my setup.I set my CG to 3.5 inches aft of the leading edge by placing the battery ~ 1 cm behind the wing skin trailing edge. . .after which I did my first hover with it. . .sure I was in my room supporting it with my hand. . but it looks like all systems are go once I get new pushrods made!No maiden today though, here is the SAC ASOS (note that right now there is a NWS advisory on the TC that two funnel clouds have touched down near me): Sacramento CA [KSMF] hourly observation on the 21st at 1:53pm PST (2153Z)wind 290° at 18 knots, visibility 1 miles, funnel cloud, thunderstorms with heavy rain, mist, 1,700 feet broken, 5,000 feet broken, 6,500 feet overcast, temperature 15°C (59°F), dewpoint 13°C (55°F), altimeter 29.75 FUNNEL CLOUD B47, automated station with precipitation discriminator, thunderstorms began at 36 minutes past the hour, rain began at 33 minutes past the hour, sea level pressure 29.75" Hg (1007.3 hPa) FUNNEL CLOUD 2SE, continuous lightning cloud-to-ground all quadrants, thunderstorms all quadrants, 0.35 inch (water equivalent) of precipitation in the previous hour, temperature 15.0°C (59.0°F), dewpoint 12.8°C (55.0°F).