Well,

Through the wonders of modern debt technology, ie. a Credit Card, I should soon be in posession of the Raven from

www.3dfoamy.com I am building one of these as a gift for a nephew, and one for me pretty soon.

My specs are

Plane: 3D Foamy Raven "Pro" package with Depron and G-Force wing, and Carbon Fiber Landing Gear kit.

Powerplant: AXI 2212/34

Prop: APC 11x4.7

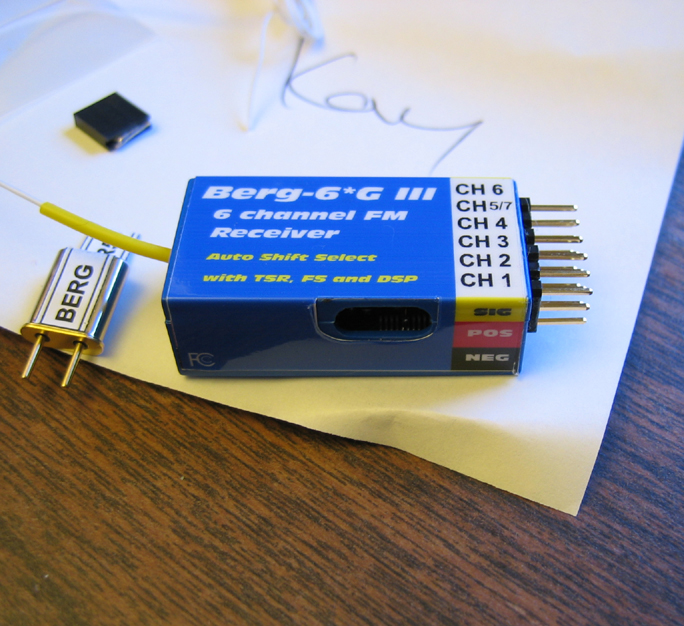

Receiver: Berg 6*G III

Electronic speed control: Castle Creations Phoenix 10

Servos: (4) Hitec Hs-55 sub micros

two 6 inch servo extensions

Testors Spray Enamel in Dark Red 1207 , Black 1247, Gold 1244, Dark Blue 1211, Silver 1246 (mist over blue canopy), and a Testors Gold Paint Marker (I wish I bought this sooner, it works great!)

Batteries: Apogee High Discharge 830 mAh 3cell Lithium Polymer packs

Apache 2500 LiPo Safe Charger (LiPo packs are known to blow up, like. . . for real!)

All up ready to fly weight with Apogee 830 3 cell, and after a few rebuilds, and a top creations AXI stick mount is now 12.9 oz.

Some of the needed gear has already arrived, but I am still waiting on the Kit, motor, Batteries, Charger.

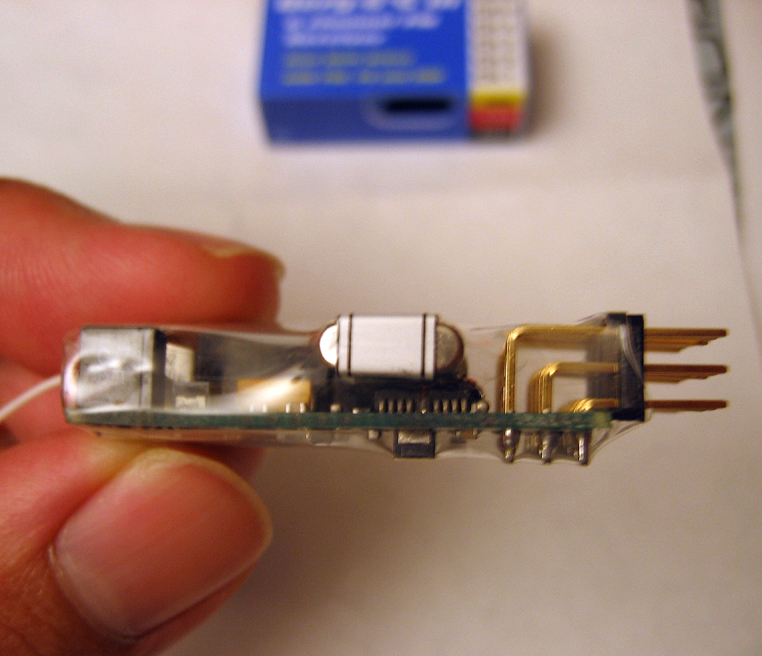

Here is the Berg 6* G III Receiver as it came out of the package today. These are very small, light, and jam packed with awesome features, see the link below if interested.

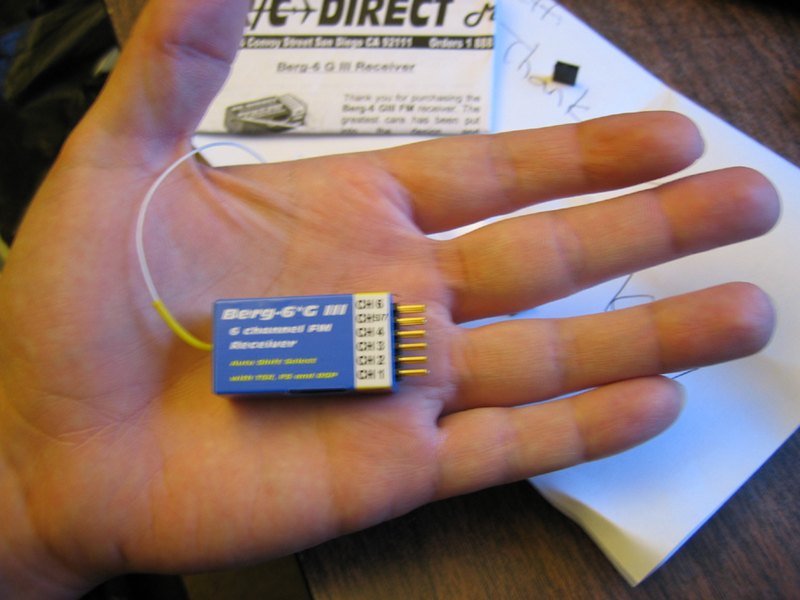

See, it's pretty small. . . and as I said pretty light at 13 grams. . .but. . .

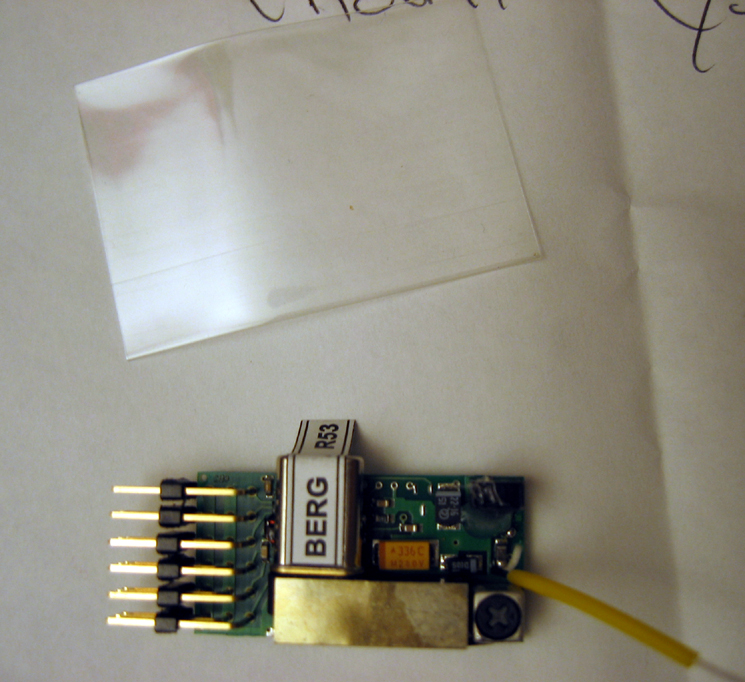

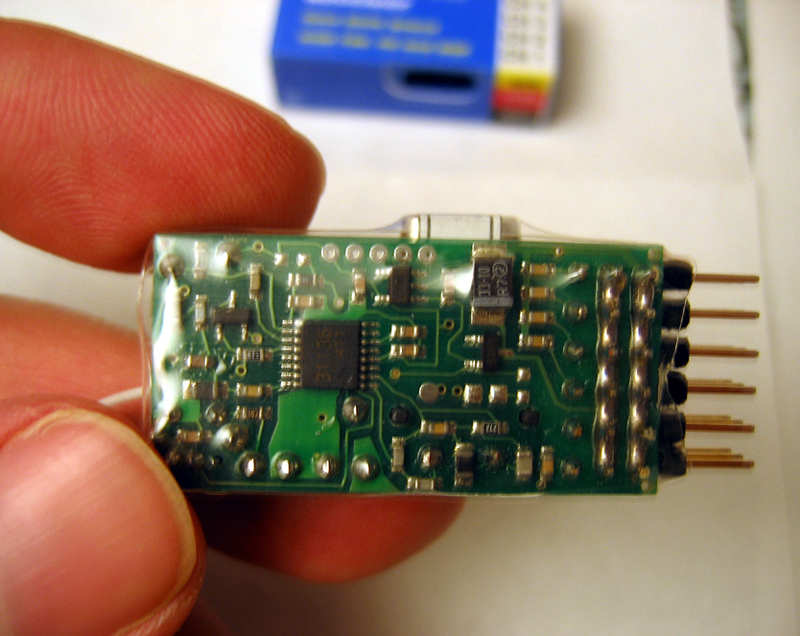

Slide a notecard under the adhesive opposite the Crystal and gently lift it off and you can open the case as seen here.

Which gives you this and saves you 3.5 grams off the total weight!

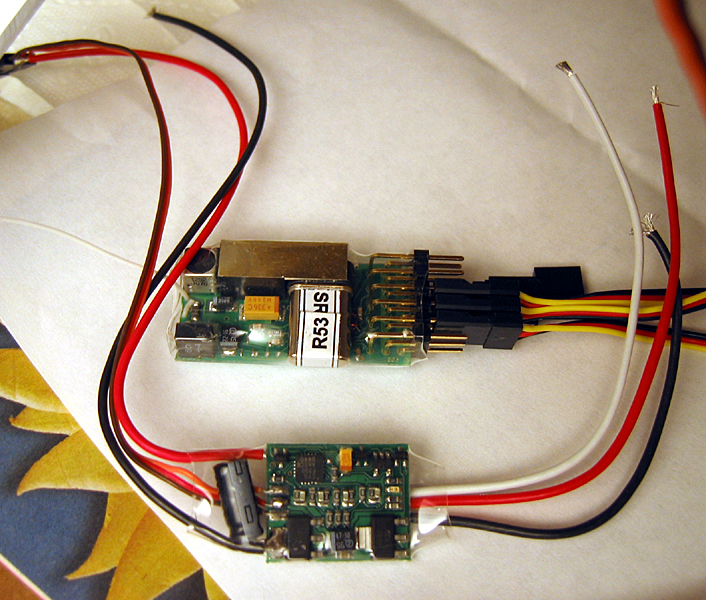

Berg is nice enough to provide some pre-cut shrink wrap along with the Receiver

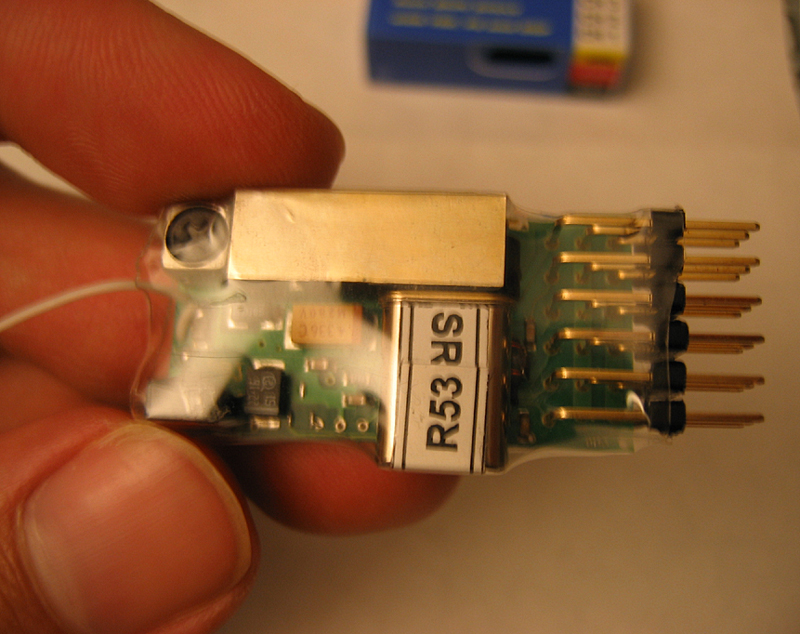

Install the Crystal, then place the bare receiver inside the shrink wrap tube and gently heat with heat gun (blow dryer) or as I did you can use a Iron-on covering iron *near* but not touching it. to shrink the tubing tight around the board. I also trimmed the extra wrap off the ends a bit, mine won't need much protection from the elements anyway.

Here is a side view once it's wrapped.

And just to be complete about it, here is the bottom of the receiver.

Here is the Castle Creations Phoenix 10 ESC next to the receiver. . . this little wonder is dwarfed even by the Berg Receiver. This is also shrink wrapped but that is how it comes from the manufacturer. Most of the weight of this is the wires.

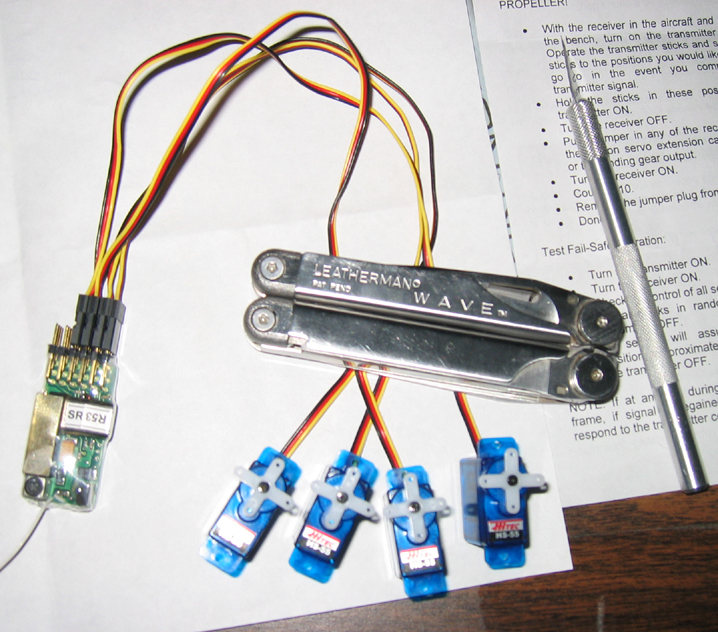

And while we are on the subject of small, here I am getting ready to test the servos and receiver. These little servos are interesting in their transparent blue cases, and they sure are tiny and cute!! :-p

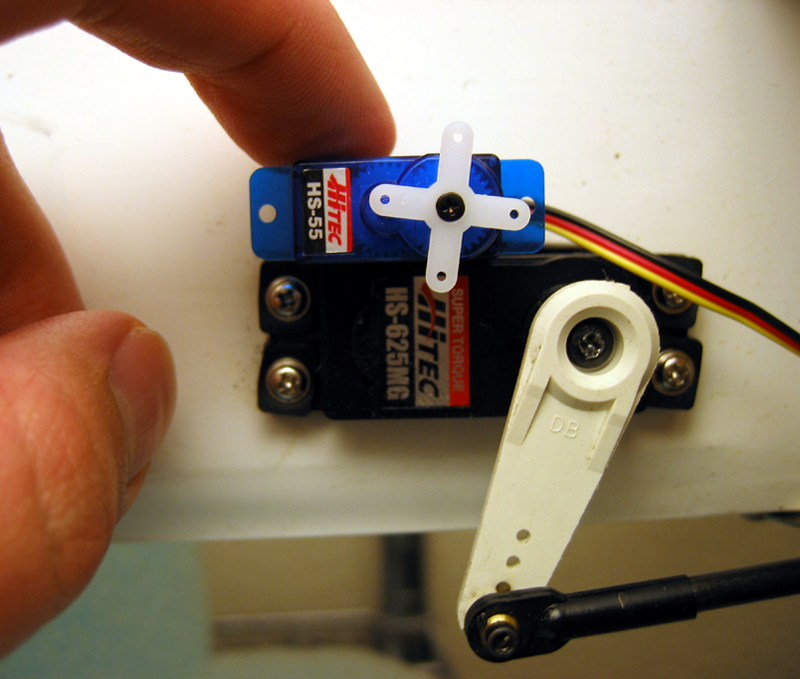

For a size comparison, here is one of the micro servos next to the HS-625MG rudder servo on my Funtana.

Berg Rx:

http://www.aeromicro.com/berg6g3.htmPhoenix 10 ESC:

http://www.castlecreations.com/products/airplane/brushless/phoenix-10.htmlBut I got mine, as well as the the servos, from towehobbies with 20.00 off my order :-D